Plate Heat Exchanger Performance Audits

Thorough Testing and Analysis to Keep Your Unit Running Optimally

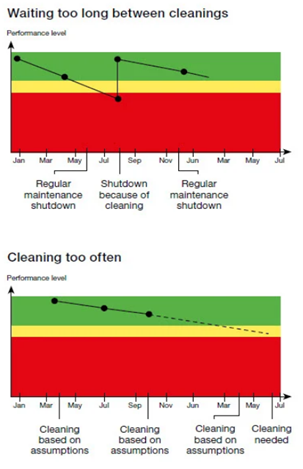

Servicing heat exchanger units when maintenance is truly required ensures maximum uptime and avoids unnecessary expenses related to excessive servicing, such as cleaning fluid and maintenance costs. On the other hand, allowing scale and other deposits to build up within your unit will reduce its energy efficiency, decrease productivity, and increase operating costs.

AlfaCheck Testing

AlfaCheck testing provides an accurate estimate of gradual fouling and deterioration without the need for a disassembly of the unit or an inspection of its individual parts. Specialized equipment is set up in conjunction with the unit’s media flow path to collect data on both temperature fluctuations and flow patterns.

The testing process is performed with a portable logger and the recovered data is then analyzed with thermal analysis software to determine the internal condition of the unit. The findings are summarized into a comprehensive report informing the client whether reconditioning of certain parts is necessary immediately, or if it can be performed at a later date.

The results are compared against a benchmark to generate a result on a simple colour-code scale, as explained below:

| Colour Result | Performance Level | Suggested Action |

|---|---|---|

| (Green) | High | No Action Required. |

| (Yellow) | Intermediate | Plan for servicing in the near future. |

| (Red) | Low | Schedule immediate servicing. |

Based on these results, you can make an informed decision regarding servicing intervals and maintenance budgets; cleaning your unit at the right time has the following benefits:

- Performance Optimization

- Increased Uptime

- Increased Heat Recovery and Energy Efficiency

- Increased Production Capacity

- Superior Product Quality

- Reduced Environmental

Footprint

Consider the following sample calculation using a large plate heat exchanger* to see a tangible financial representation of the effects of on-time servicing:

System Parameters:

- Average Daily Flow Rate at 1000 gallons/minute: 1.44 x 106 gallons/day

- Average Daily Heat Transfer at 14.5 million BTU/hour: 3.48 x 108 BTU/day

- Level of Fouling Corresponding to 15% Energy Transfer Losses

Daily Losses:

3.48 x 108 BTU/day x 15%

= 5.22 x 107 BTU/day

= 522 thm/day

Assuming Energy Costs of $1/thm:

522 thm/day x $1/thm

= $522/day

For a single, large-sized plate heat exchanger unit, the savings compared with 2 months of operating under fouling conditions can amount to upwards of $31,000.

*Based on an Alfa Laval M30 Heat Exchanger (300 mm/11.8” inlet diameter)

Visual Condition Assessment

Using thermal imaging technology, thermal performance of gasketed plate heat exchangers can be assessed within minutes, while operating under normal conditions within your process. Based on this analysis, recommendations regarding upgrades, short and long-term maintenance, spare parts, and performance optimization are made.

The subsequent report will provide information regarding the mechanical condition of the unit, remaining gasket lifetime predictions, pictures and descriptions of problematic sections of the unit, a thermal imaging analysis, and a summary of findings.

A visual condition assessment provides the opportunity to better perform regular maintenance instead of break-down repairs, preventing unnecessary downtime from reducing system efficiency and profitably.

Not the service that you’re looking for?

Click here to see the other services we offer.