Exhaust Gas Heat Exchanger and Header Tank Heat Exchangers

Alfa Laval Micro

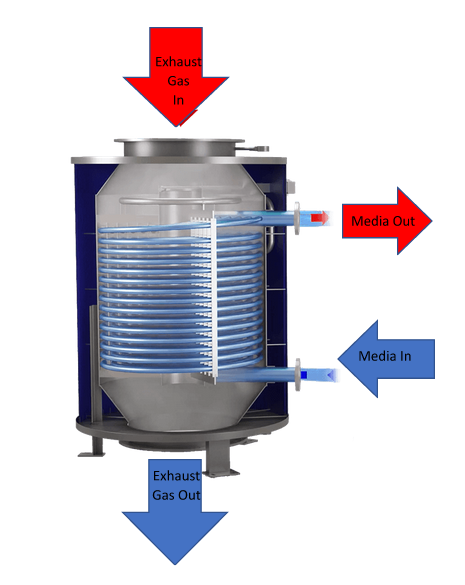

The Alfa Laval Micro is a compact exhaust gas heat exchanger designed to recover waste heat from process flue gases, turbines, and engine exhaust. The Micro is a quintessential example of realizing energy efficiencies in a production process or a system with waste exhaust heat. By using this product, you are helping to reduce your organization’s carbon footprint. Valutech is the Alfa Laval Micro Heat Exchanger distributor for the province of Ontario.

The Micro can be installed indoors or outdoors, in a vertical or horizontal configuration, and offers year-round energy savings potential in a compact size for an economical investment. The Micro Exhaust Gas Heat Exchangers can be used to heat any variety of medium; water, steam, tri-ethylene-glycol, and any industrial thermal oils. The Micro can accommodate exhaust gases at temperatures of up to 600°C and can recover heat up to approximately 5,000 kW.

How it Works

Cold side fluids (Media)

- Hot water

District heating, HVAC, process applications, ORC (electricity) etc.

- TEG (Tri-ethylene-glycol)

District heating, HVAC, process application, ORC (electricity) etc.

- Thermal oils

Steam generation

Cleaning using Dry Run

Dry run Micro on media side while exhaust gas is passing through.

Let the pyrolysis process take place- letting the hot exhaust gas clean the outside of the heating surface.

Adjustment by regulation damper

A built-in regulation damper makes it possible to re-direct a certain part of the exhaust gas away from the heating surface. Thereby the “output” can be adjusted. Some examples are;

- Hot water temperature/ volume can be adjusted

- Evaporator pressure can be controlled

- Superheater temperature can be adjusted

Features

- Water tube coil design with serrated spiral fin tubes

- Integrated regulation damper

- Integrated cleaning device

Values

- More up-time

- Less space occupied & relatively lower investment

- Less downtime

- No exceed production

- Easy to retrofit & optimum space utilization

Features

- Low media volume

- Extended heating surface

- No external by-pass needed

- Dry-run possible

- Adjustments during operation

- Ability to clean the heating surface during operation by using water, steam or compressed air

- Horizontal & vertical version for in & outdoor installation

- Low inertia

- Lower footprint & weight

- Cleaning possible during operation of engine, turbine or process

- Output can be adjusted according to the need

- Extend the time in between major cleaning e.g. via dry-run mode

- Flexibility

Technical data & Dimensions

| Weight (incl. insulation) | 400 kg to 3900 kg |

| Diameter (incl. insulation) | 950 to 1870 mm |

| Height (incl. insulation) | 1700 to 2800 mm |

| Media inlet/outlet header | 40″ |

| Exhaust inlet/outlet header | 18” to 40” |

| Insulation | 150mm |

| Capacity | 250 – 5000 kW |

| Exhaust Gas Side | |

| Maximum inlet temperature | 600 °C (dry-run 530 °C) |

| Minimum outlet temperature | Dependent on engine fuel and exhaust gas composition |

| Pressure Loss | According to customer requirement |

Standard range available for quick delivery.

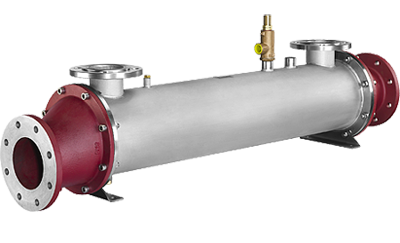

- Suitable for engines up to 1MW.

- Suitable for use with engines powered by conventional or alternative fuels.

- Fully welded stainless steel construction for reliability and durability.

- Can also be used to extract energy from gas or air and transfer it to a water circuit.

- Compact and efficient design for ease of installation.

- Ideal for reducing the exit temperature of the exhaust gases in hazardous areas.

- Used in conjunction with jacket water, charge air, fuel and oil coolers, Bowman units can reclaim up to 60% of waste heat from an engine.

- Bowman units when fitted provide FREE HEATING & HOTWATER.

Given the following information, we can recommend a unit for your requirements:

- Fuel type

- Exhaust gas mass flow rate

- Exhaust gas inlet temperature

- Water circuit inlet temperature and flow rate

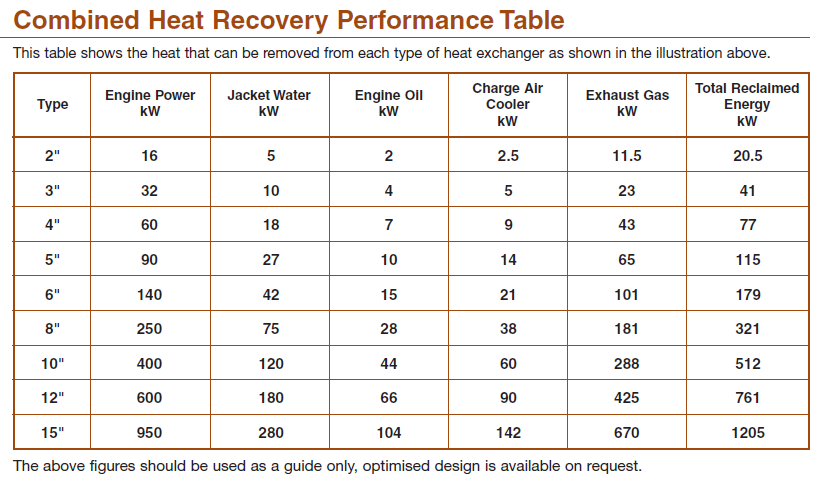

Exhaust Gas Heat Exchanger Performance Table

Typical examples of exhaust gas heat exchanger performance

The figures below are a general guide only and are not based on any particular natural gas engine. They assume an air/fuel ratio of 10.23 : 1 by volume, a fuel consumption of 0.34m3/kWh (measured at 1.013 bar and 15ºC) and an exhaust gas temperature of 600ºC and a water inlet temperature of 80ºC.

Visit our other related product pages:

Header Tank Heat Exchanger

Charge Air Coolers

Hydraulic Oil Coolers