Alfa Laval Tube-in-Tube Heat Exchangers

Customizable Heating and Cooling Modules for Particulate Sludges

Valutech offers Alfa Laval Tube-in-Tube heat exchangers that are specifically designed for the heating and cooling of liquids containing fibers or particles; this makes it ideal for applications such as beverages containing suspended solids or pulps such as juice and wine.

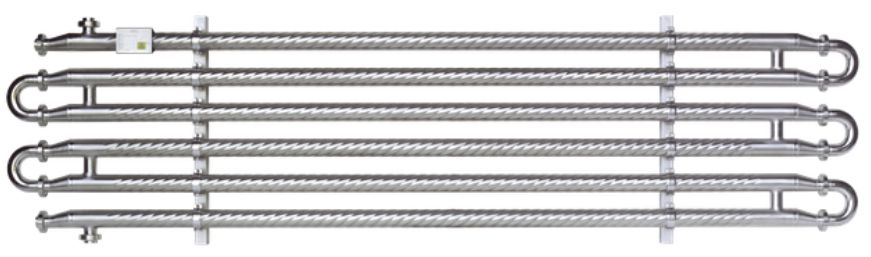

ViscoLine™

Alfa Laval’s ViscoLine™ series of tube-in-tube heat exchangers are designed to gently handle viscous food and beverage media that plate exchangers cannot handle without clogging or reduced effectiveness. Corrugated and other advanced profiles allow for more turbulent flow and increase heat transfer efficiency.

The ViscoLine™ series is ideal for processes that contain: heat-sensitive products, high-purity water for pharmaceutical, biotech, and personal care applications, and low to medium viscosity food products with or without particulates and fibers.

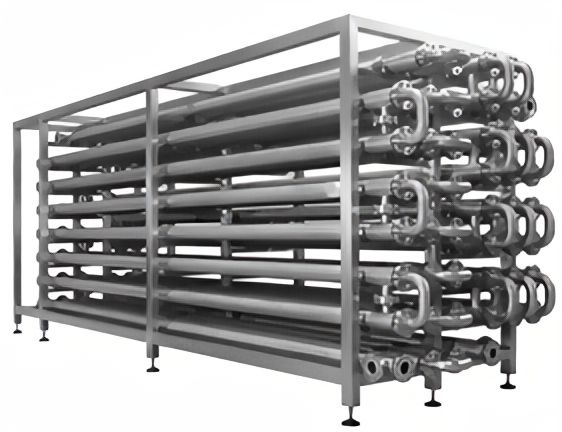

The design is based on having the product flow counter-currently through the inner tube, and. features a fully-welded construction with a bellow-on-shell tube to counteract thermal expansion effects. Alfa Laval Tube-in-Tube heat exchangers can be used in series, are possible to be mounted on frames, and the layout can be customized to suit the system footprint. It can also be used in aseptic processing applications.

The Tube-in-Tube model features the following design specifications:

- Module Length: 10 or 20 ft

- Product Tube Outer Diameter: 4.5”

- Service Tube Outer Diameter: 6.6”

- Maximum Service-Side Design Pressure: 145 psig

- Maximum Product-Side Design Pressure: 218 psig

- Maximum Design Temperature: 230 °F

- Maximum Heat Transfer Area: 33.5 ft2

- Maximum Flow Rate: 506 GPM

The following ViscoLine™ models are available:

- ViscoLine™ Multitube (VLM): Standard model for viscous food products; used for heating/cooling and pasteurization of low to medium viscosity products that can contain fibers/particulates.

- ViscoLine™ Monotube (VLO): For products containing large particles, or a high pulp/fiber content.

- ViscoLine™ Annular (VLA): For high viscosity products that must be heated from both sides.

- ViscoLine™ Regenerator (VLR): For product heat recovery via a counter-current flow set-up.

- ViscoLine™ CIP (VLC): For hot water and CIP solutions that can contain fibers/particulates; can be used for general heating and cooling.

All ViscoLine™ units have the following benefits:

- Possible integration of modules on a support or full frame.

- Different models can be combined on the same frame, as well as with other types of heat exchangers.

- Retrofitting/expansion is possible at any time.

- Fully welded construction with multiple possible connection types.

Pharma-line Point of Use

Alfa Laval’s Pharma-line Point of Use module is designed for point-of-use cooling of pharmaceutical water systems; as such it meets the most stringent hygienic industrial standards, and even remains sanitary even when in standby mode. The plug-and-play module acts as a sub-loop within the system, contains no internal welds, and is fully drainable on the product side.

The Pharma-line Point of Use contains no internal gaskets, making it virtually maintenance-free, with a low hold-up volume allowing for access cooled water to within seconds of beginning operation. It is available in four sizes, with heat transfer areas ranging from 3.2 to 10.8 ft2.

Point of Use features the following design specifications:

- Surface Finish: Ra ≤ 20 µin

- Max Flow Rate: 396 GPH

- Max Design Pressure: 145 psi

- Max Design Temperature: 302°F