Plate Heat Exchangers as High-Rise Pressure Breakers

Take Advantage of Capital and Operating Cost Savings via High-Efficiency Protection

As buildings become taller, the higher the static pressure that HVAC equipment like boilers, chillers, pumps, and their associated automation equipment is exposed to. This applies to any equipment that is not located at the highest point of a building’s hydronic loop, and when you consider that the majority of such equipment is located in the building basement, boilers and chillers in high-rise buildings are often bearing the full brunt of the hydronic loop static pressure. In the absence of heat exchangers used to break this static pressure, HVAC equipment must be designed to withstand these pressures. It is common practice however, to use plate heat exchangers as interchangers at regular intervals along the height of high-rise buildings in order to be able to use HVAC equipment with standard pressure ratings.

At a certain point, pressure breakers become necessary as even the highest-rated equipment cannot cope with high levels of static pressure. Each heat exchanger used creates a zone on either side, with most high-rise buildings needing a single unit (two zones); the tallest buildings in the world (700 or more meters in height) may use up to 3 units (four zones).

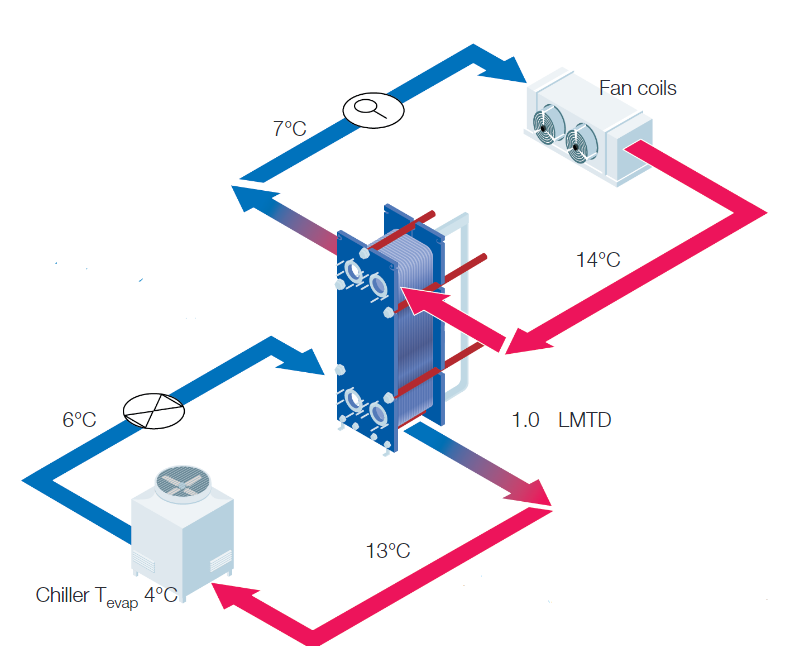

Each zone added necessitates operating the chiller or boiler at a higher load in order to overcome the intrinsic temperature differential created by using the heat exchanger(s). Systems should be designed to maintain similar loop temperatures in each zone, ensuring that the zone furthest from the equipment is satisfied; otherwise (in the case of building with HVAC equipment located in the basement), fan coils in higher zones will not receive water at the temperatures they require. Thus, the efficiency of the plate heat exchanger chosen directly relates to the load that the chiller or boiler operates at; the closer the approach that can be achieved, the lower the energy costs associated with heating and cooling.

Alfa Laval gasketed plate-and-frame heat exchangers are used in the world’s ten tallest buildings as interchangers due to their high efficiency, allowing for approach temperatures of 1°C or lower. While investing in plate heat exchanger as an interchanger cuts down on capital costs, investing in an efficient unit will provide long-term operating cost savings in the form of the energy costs that would otherwise be higher with a less efficient heat exchanger. For more information on the importance of servicing plate heat exchangers in free cooling applications, please refer to this explanation.

Practical Application – Plate Heat Exchangers as Pressure Breakers

Plate reconditioning services allow for gasketed plate-and-frame heat exchangers to approach their peak efficiency, creating energy saving opportunities by maintaining a higher level of efficiency with consistent conditioning over the course of the lifetime of the unit. For example, plate reconditioning services offer a quantifiable benefit in terms of reduced energy consumption in high-rise pressure breaker applications. Of course, these benefits can be observed operating cost savings associated with that reduction, but maintaining a higher average efficiency also contributes towards sustainable operation of heat exchangers in HVAC applications.

Consider a high-rise building with the boiler located in the basement and a 3 million BTU/h (30 therms) heating requirement, with one plate heat exchanger used as an interchanger. The topmost zone of the building requires hot water at 160°F, and the system is initially designed with a temperature approach of 5°F. As the plate heat exchanger fouls over the course of usage, the boiler will have to supply water at progressive hotter temperatures to maintain the temperature requirement of the topmost zone. In this case, the loss in efficiency of the heat exchanger unit means that the boiler must supply water at 175°F. As a rule of thumb, for every 10°F hotter that a boiler operates at, a 4% loss in efficiency can be observed. Thus, assuming the initial boiler efficiency was 80%, this 30-therm system will progress from demanding 37.5 therms to 39.5 therms of energy input to the boiler. Assuming that heating is required for 7 months per year (213 days/year), and that natural gas costs $1.00/therm, the 5.3% increase in energy demands that result from fouling of the heat exchanger will lead to additional energy costs of over $10,000 per year. These values are typical for boilers with efficiencies in the anywhere in the range of 70%-90%. Based on these calculations of a typical scenario, which does not account for chiller operation, it is clear that consistent maintenance of plate heat exchangers used as pressure breakers in high-rise buildings is critical for reducing energy costs and operating sustainably.