Gestra Steam Traps

Steam traps play a vital role in discharging condensate produced as a result of trapped steam in a heating system.

Three types of steam traps:

BK: The BK trap is a thermostatic steam trap with a bimetallic regulator which is particularly robust – BK 45/46

These steam traps are insensitive to frost and water hammer, resistant to corrosion and require little maintenance.

The traps regulate the flow of medium using a highly responsive Thermovit regulator. Specially shaped bimetallic plates arranged one above the other expand as the media temperature rises, moving the stage nozzle. The flow orifice closes. In the cold state, the regulator is fully open. That is why steam traps from the BK series boast an excellent start-up performance.

Key Data:

DN 15 -25 (½” – 1″)

PN 40 / CLASS 300

Max. differential pressure: 22/32 bar

Easy-to-install RHOMBUSline body with recessed body gasket and metal base bushing

Integrated non-return valve action

Dirt strainer with large surface area (Y-strainer)

Technical data: Bimetallic steam traps – BK

MK: The MK trap is a thermostatic trap with a membrane regulator and has very sensitive response characteristics.

Thermostatic steam traps for removing condensate from steam or for venting steam pipes

A distinguishing feature of the MK series is the outstanding responsiveness of the membrane regulator. It is especially suitable for heat exchangers whose operation is adversely affected even by minimal banking-up of condensate.

USE

Highly responsive steam trap for draining heating processes.

Especially recommended for use in:

Saturated steam pipes

Trace heaters

Heating coils

Air heaters

Steam roller presses/iron presses

Tyre presses

Moreover, the MK series is ideal for use as an extremely fast-acting air vent.

ADVANTAGES

- Extremely fast response by the GESTRA thermostatic capsule

- Flat or tandem seal

- No loss of steam

- Function uninfluenced by upstream or back pressure

- Any installation position – in horizontal or vertical pipes

- Large hot water flowrates even at low differential pressure

- Inner parts made of corrosion-resistant stainless steel

- Wear-resistant membrane film of Hastelloy

- Three different types of membrane for different areas of use

- Long service lifer

Technical data: Steam traps with membrane regulator – MK Series

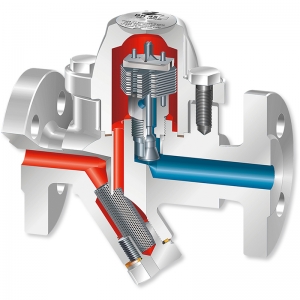

UNA: Ball-float steam traps for condensate discharges at extreme and sudden flowrate and pressure fluctuations.

Float steam traps with ball float for removing condensate from steam, cold condensate or distillates without banking-up

The traps with the tried and tested rolling ball seal work with exceptionally low friction and therefore have very low actuating forces. They are durable and guarantee maximum tightness.

USE

Universal steam trap for virtually all requirements. Especially recommended for the drainage of

Steam-regulated heat exchangers

Systems with a high condensate flowrate

Steam manifolds

Steam driers, gas driers, cyclone separators

Systems with very small operating pressures, very low differential pressure and extremely variable operating conditions

Vacuum systems

Gas and compressed air lines

Drying cylinders

The series is also ideal as a discharge controller on flash tanks and feedwater tanks.

Advantages:

- Reliable function regardless of back pressure and condensate temperature

- No loss of steam thanks to the formation of a water seal

- Maximum tightness and durability as well as excellent control characteristics, as the sealing unit of the regulator has a rolling or segmented ball

- Immediate response level control without automatic venting – Simplex version

- With automatic, fast-acting venting for steam systems – Duplex version

- Especially insensitive to dirt

- Inner parts made of corrosion-resistant stainless steel

- Fully operational even when back pressure is nearly 100% of upstream pressure

- Can be serviced without removing the body

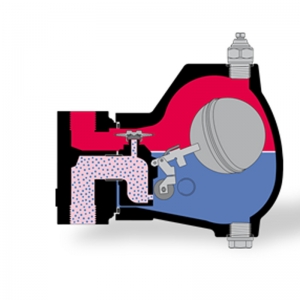

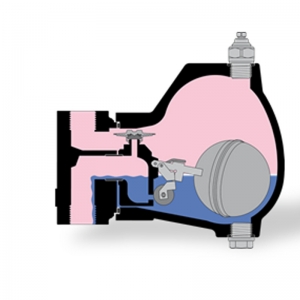

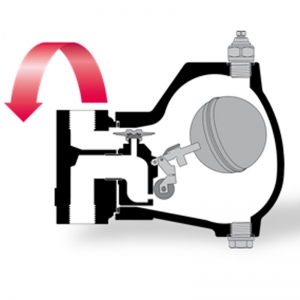

Method of Operation

Automatic, temperature-dependent venting through thermostatic capsule.

Cold condensate and air are discharged.

The rolling ball valve is actuated directly by the float, based on the condensate flowrate.

The direction of flow through the steam trap (horizontal or vertical) can be changed (from left to right or from right to left) by repositioning the body