High Speed Separators

Industrial Water-Based Fluids

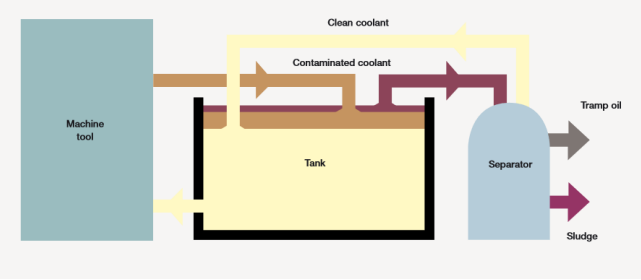

The installation of a high-speed centrifugal separator is proven sustainable technology, treat contaminated industrial fluids by dramatically reducing the volume of waste that must be sent to disposal sites. This technology helps create a healthier working environment by reducing bacterial growth, along with reduced machinery wear and tear, fewer rejects, and an overall improvement in quality.

| Model | Alfie 200 | Alfie 500 | AlfaPure S2 | AlfaPure S3 | AlfaPure S7 |

|---|---|---|---|---|---|

| Max Coolant Flow Range | 280 l/h (1.2 US gpm) | 500 l/h (2.2 gpm) | 900-2000 l/h (3.96 – 8.8 gpm) | 600-3000 l/h (2.64 – 13.2 gpm) | 5000–7000 l/h (22–31 gpm) |

| Max Temp | 50°C (122°F) | 70°C (160°F) | 80°C (176°F) | 80°C (176°F) | 100°C (212°F) |

| pH Value | 6 – 9 | 6 – 9 | 6 – 13 | 6 – 14 | 6 – 14 |

| Weight | 14 kg (31 lbs) | 60 kg (135 lbs) | 500 kg (1100 lbs) | 616 kg (1358 lbs) | 616 kg (1358 lbs) |

| Dimension | Height 520 mm (20″) Recommended free space above tank 750 mm (30″) Min. tank depth 200 mm (8″) |

Length 620 mm (24″) Width 510 mm (20″) Height 1140 mm (45″) |

Length 1550 mm (61”) Width 900 mm (35.4”) Height 1448 mm (57”) |

Length 700 mm (27.5”) Width 900 (35.4”) Height 1555 mm (61”) |

Length 2040 mm (8.3”) Height 2450 mm (0.45 inch) Width 1260 mm (1.6”) |

Alfie 200

This compact, stationary unit is designed to remove contaminants from coolants in smaller systems. Below the separator is a bellows that automatically adapts the inlet to the level of fluid in the tank.

Alfie 200 is extremely easy to use. Anyone can learn how to operate and maintain Alfie in a few minutes. It is fast and easy to clean the separator – the casing is lifted off manually in a few easy movements and any sediment collected inside the bowl is brushed off.

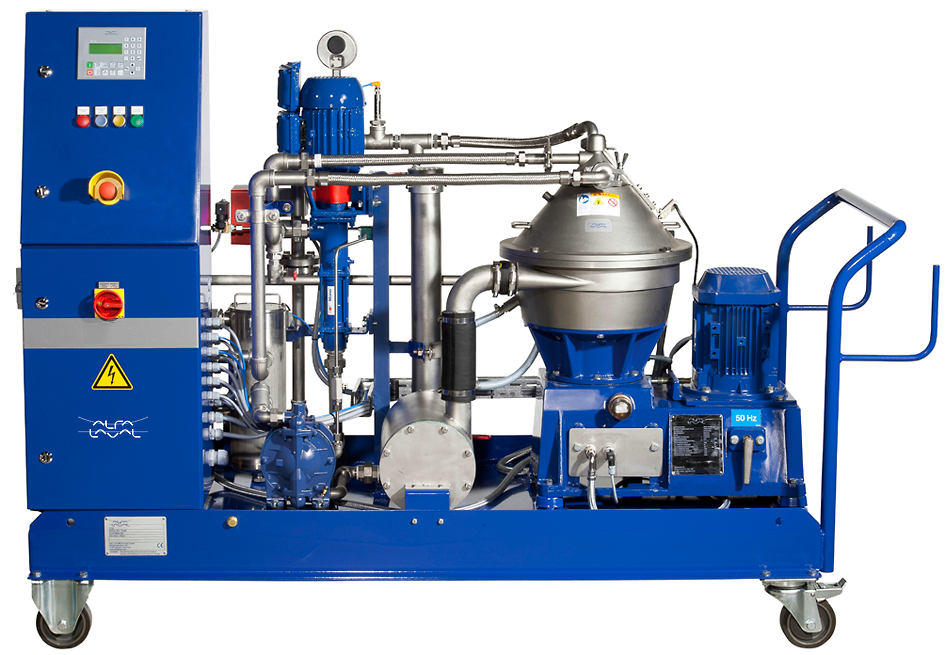

Alfie 500

This mobile unit removes contaminating oil, grease and solid particles from coolants. It comes with a complete system including separator, feed pump and control system. The control panel makes it easy to operate this mobile unit.

The Alfie 500 has a high capacity-to-size ratio, handling tanks up to 4000 gallons. The module is typically installed in a bypass mode and operates continuously. Quick couplings make it easy to connect the hoses when the cleaning unit is moved from tank to tank.

With its compact and ergonomic design, Alfie 500 is easy to move across the workshop floor and can be used to serve one or several tanks. This unit includes a floating suction device, a set of tools, test report, certificate of origin and test manual. The floating suction device is recommended for deeper tanks with a liquid depth of 4 inches or more.

AlfaPure

Alfa Laval’s AlfaPure reduces tool wear, so you benefit from more precise machining, fewer rejects and a longer service life. It also creates healthier working conditions and reduces your disposal costs.

This easy to operate unit is normally installed in a bypass module, operating continuously without interrupting machinery operations. The basic user interface is equipped with flow and pressure indicators. Three module types are available for your specific fluid processing needs.

AlfaPure S2

- Concentrator, Purifier, & Clarifier

- Stationary or Mobile Unit

AlfaPure S3

- Concentrator

- Stationary or Mobile Unit

AlfaPure S7

- Concentrator

- Stationary Unit