Boiler Isolation via Gasketed Plate-and-Frame Heat Exchangers

Protect Your Boiler System, Reap Energy Savings, and Operate Sustainably

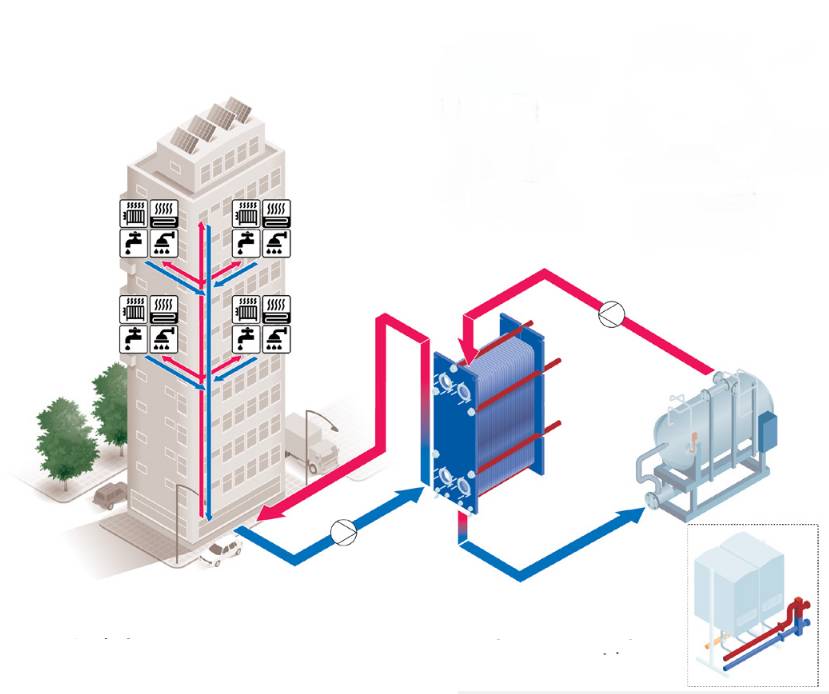

A gasketed plate-and-frame heat exchanger between the boiler water and building loop in a domestic water heating application provides protection to the boiler from macroscopic debris and precipitating solutes that are periodically introduced to the building side of the system. In addition, boiler isolation has the advantage of preventing oxygen permeation within the boiler-side loop, reducing the risk of boiler tube corrosion.

In a system where the boiler is not isolated from the building loop, it will be exposed to hard make-up water containing solutes every time a leak occurs or when the system has to drained, flushed, or otherwise maintained. The large majority of the solutes that are introduced to the system will precipitate rapidly on the boiler tubes, where the wall temperature can exceed 1000°F; the primary solute of concern in this case is calcium carbonate (CaCO3), the solubility of which is inversely proportional to temperature. In other words, CaCO3 will tend to precipitate on the boiler tubes, the hottest point within the system.

Conversely, using a gasketed plate-and-frame heat exchanger to isolate the boiler loop ensures that the boiler side will be drained relatively infrequently, while creating a simpler loop with significantly less opportunity for the introduction of foreign contaminants. When precipitate and debris block the narrow flow passage in the boiler tubes, the efficiency of the boiler is reduced and more energy has to be spent to achieve the heating needs of the system, leading to higher operating costs. It is estimated that for every millimetre of principate build-up on the boiler tubes, an increase of up to 12% in fuel costs can be observed.

In addition, the maintenance of boiler tubes is significantly more expensive and difficult with respect to that which would be performed on a gasketed plate-and-frame heat exchanger, meaning that boiler isolation will pay significant dividends in terms of labour costs and the costs associated with the replacement of an unprotected boiler. Further, since the water on the building side will never be exposed to temperatures as high as those near the boiler tube walls, and since flow within the heat exchanger is turbulent, the precipitation on the building side will occur at a significantly lower rate with respect to an unprotected system.

As an example of fuel savings arising from boiler isolation, consider two otherwise identical buildings (equivalent construction, same compound estate, independent and identical natural gas boilers), only one of which is taking advantage of boiler isolation. Over the course of several years of operation, the unprotected boiler will see its efficiency drop to 75%, while the protected unit will be able to maintain its rated boiler efficiency at 85%. Assuming that the heat load of the building is 3 million BTU/h (30 therms), a protected boiler operating at 85% efficiency will require 35.3 therms of energy input to heat its respective building. The unprotected unit will need 40 therms to achieve the same level of heating, however; this means that using an unprotected boiler will result in energy bills that are over 13% larger with respect to an isolated unit. Assuming that heating is required for 7 months per year (213 days/year), and an energy cost of $1.00/therm, the extra 4.7 therms afforded by maintaining efficiency via boiler isolation can save over $24,000 a year in operating costs alone.

A secondary benefit of boiler isolation is the reduction of exposure to oxygenated water; every time radiator flushing or air venting is performed, oxygen dissolves into the building water loop, creating a risk of corroding ferrous components. Not only will a gasketed plate-and-frame heat exchanger isolate the boiler from oxygenated water, the use of stainless-steel plates in a gasketed plate-and-frame heat exchanger will also reduce the risk of corrosion on the building side of the system as well. Boiler isolation therefore contributes to sustainable operation in two ways; firstly, the long-term efficiency of the system will be significantly increased, reducing the demand for fuel generation at the cost of the environment. Secondly, boilers will last longer, reducing the need to devote unnecessary energy and material resources towards manufacturing and installing new boilers in unprotected systems.