Free Cooling

Take Advantage of Energy Savings Through Sustainable Operation

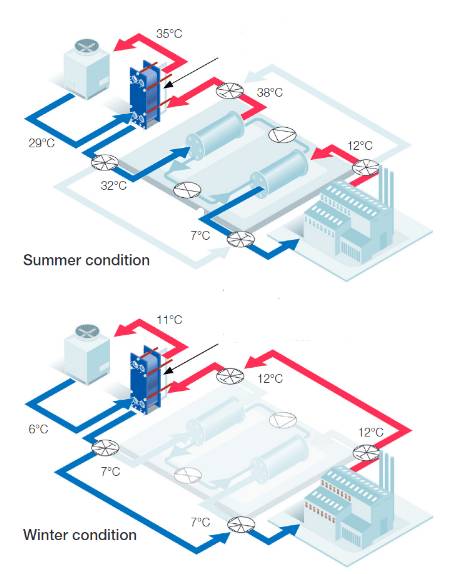

During the colder months of the year, chillers in industrial processes can be bypassed by water chilled via free cooling. This opens up the opportunity to turn off chiller systems that are a large source of energy consumption within industrial processes, leading to energy savings and more sustainable year-round operation. When ambient temperatures drop below a certain threshold, water from cooling towers can be supplied at temperatures sufficient for an existing industrial process.

The use of a gasketed plate-and-frame heat exchanger under both winter and summer operating conditions allows for filtration of debris and solutes that enter the open cooling tower, ensuring that the condenser is protected in the summer, and process water is contaminant-free year-round. Ensuring a pressure drop threshold of around 80 kPa (11.6 psi) further reduces the risk of fouling when considering seasonal fluctuations in cooling water demands. During the shoulder months, chiller bypass can also be performed intermittently (also known as hybrid cooling) for hours or days at a time, based on ambient temperatures during that period.

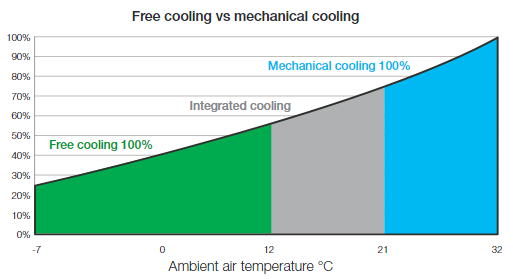

Consider that in Canada, one can expect the ambient air temperature to be at or below 8°C at virtually all times from mid-October to mid-April; this is a half-year stretch where free cooling can be expected to be used at all times with a typical gasketed plate-and-frame heat exchanger. The graph on the left illustrates the percentage of the maximum load that a cooling system operates at with respect to ambient air temperatures, indicating the rough cut-off points for total free cooling, hybrid cooling, and mechanical cooling (via continual chiller use).

During the coldest period (hereafter referred to as the ‘free cooling period’) a chiller would operate at roughly 40% of its maximum load on average; for a typically-large chiller within a 500 ton cooling system, this would amount to 200 tons or 703 kW of its capacity being required during the free cooling period.

Supposing a coefficient of performance (COP) of 4, the cooling system has an energy demand of 176 kW during the free cooling period; treating this period as equivalent to a half-year (182 days), a typical cooling system can be expected to draw approximately 770,000 kW·h during this time. Without even accounting for the possibility of hybrid cooling, the annual operating costs savings associated with performing free cooling via chiller bypass for a typical system, at an energy cost of $0.10/kW·h can amount to $77,000. The greater the efficiency of the heat exchanger unit, the longer the chiller can be bypassed, and thus an investment in an efficient unit pays returns in terms of operating costs over its lifetime. For more information on the importance of servicing plate heat exchangers in free cooling applications, please refer to this explanation.

Practical Application – Free Cooling with Chiller Bypass

Plate reconditioning services allow for gasketed plate-and-frame heat exchangers to approach their peak efficiency, creating energy saving opportunities by maintaining a higher level of efficiency with consistent conditioning over the course of the lifetime of the unit. For example, plate reconditioning services offer a quantifiable benefit in terms of reduced energy consumption in the application of free cooling. Of course, these benefits can be observed within operating cost savings associated with that reduction, but maintaining a higher average efficiency also contributes towards sustainable operation within industrial and commercial plate heat exchanger operations.

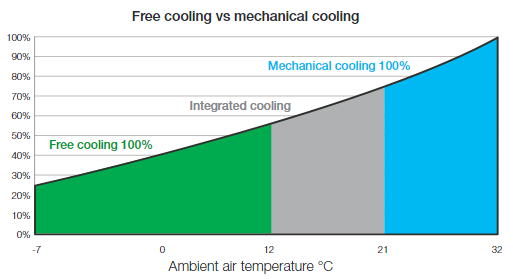

Consider a 500 ton chilling system with the option for free cooling for half of the calendar year via bypass using a gasketed plate-and-frame heat exchanger operating at 20% efficiency prior to being reconditioned. This system requires lower ambient air temperatures relative to a reconditioned unit since the cooling water feed must be maintained at a fixed temperature regardless of the time of the year. Given this requirement, the log-mean temperature difference seen in a heat exchanger with reduced efficiency must now be significantly larger. Under these conditions, free cooling cannot be performed unless ambient air temperatures are at 8°C — a significant reduction from the 12°C that is theoretically required by a heat exchanger unit that can maintain a closer log-mean temperature difference. While ambient temperatures of 8°C or lower are typical from mid-October to mid-April, one can expect that ambient temperatures of 12°C or lower are typical from the start of October to the end of April. That is, the window where free cooling is possible with a reconditioned unit is one month longer relative to a heat exchanger unit operating at 20% efficiency prior to reconditioning.

The graph on the left illustrates the percentage of the maximum load that a cooling system operates at with respect to ambient temperatures, indicating the rough cut-off points for total free cooling, integrated cooling (otherwise known as hybrid cooling, where operation switches between free cooling and intermittent chiller use), and mechanical cooling (via continual chiller use). During the two half-month periods that the use of a reconditioned heat exchanger unit adds to the free cooling period (hereafter referred to as the ‘extended period’), a chiller would operate at roughly 50% of its maximum load on average. For a typically-large chiller within a 500 ton cooling system, this would amount to 250 tons or 880 kW of its capacity being required during the extended period. Supposing a coefficient of performance (COP) of 4, the cooling system has an energy demand of 220 kW during the extended period; treating this period as equivalent to a month (30 days), a typical cooling system can be expected to draw approximately 158,260 kW·h during this time.

Based on an energy cost of $0.10/kW·h, the annual operating costs savings associated with regular reconditioning of the gasketed plate-and-frame heat exchanger within a typical cooling system can amount to $15,826. The greater the efficiency of the heat exchanger unit, the longer the chiller can be bypassed, and thus investments in reconditioning pay returns in terms of operating costs over its lifetime.