Alfa Laval Gasketed Plate & Frame Heat Exchangers

Gasketed plate-and-frame heat exchangers are the primary choice for all your heat transfer needs. We offer sustainable solutions for every modern heating and cooling application, as well as for the emerging renewable fuel and energy industries.

Valutech, based in Ontario, Canada, is a proud partner of Alfa Laval –the world’s largest manufacturer of Plate Heat Exchangers. For 2021 and beyond, we are excited to introduce Alfa Laval’s new generation of T-Series Plate heat exchangers, packed with next-gen technology to help you reach new levels of thermal efficiency.

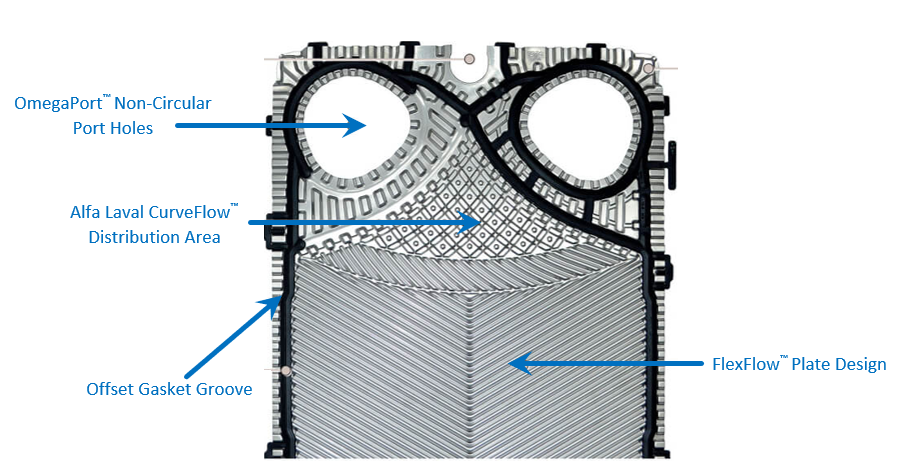

Next-Gen Features

Unique features to improve process efficiency and reliability.

Efficiency

CurveFlow™ distribution area

⦁ Improves media flow and minimizes the risk of fouling

⦁ Fully utilizes available surface area

⦁ Provides perfect distribution inside channel, unit stays clean longer

OmegaPort™ noncircular port holes

⦁ Enhances media flow and thermal efficiency

⦁ Avoids short cuts in plate pack

⦁ Pressure drop better utilized for heat transfer

Offset Gasket Groove

Ensures plate utilization for maximum heat transfer efficiency

FlexFlow™ plate design

⦁ Improves thermal efficiency and optimizes pressure drop utilization

⦁ Perfect for applications with unequal flows

⦁ Both channels stay clean longer

Reliability

Five-point alignment

Ensures reliable plate positioning and easy service of large units

SteerLock™ plate alignment

Ensures reliable plate positioning and easy service

PowerArc™ plate pattern divider

Improves plate rigidity for longer lifetime

RefTight™ sealing system

High-performance gasket sealing for high-pressure duties

Serviceability

ClipGrip™ gasket attachment

Ensures perfect seal and trouble-free maintenance

T-Bar Roller

Provides a lower unit that is easy to service

Bearing boxes

Guarantees an easy-to-open unit for smoother, more efficient maintenance

Compact frame

Facilitates maintenance and minimizes service area requirement

How it Works

See how Alfa Laval GPHE’s can be used for a variety of applications.

Liquid to Liquid

Steam Heater

Multi-Pass Designs

Flow Pattern

There are three typical flow arrangements to consider: parallel, counter and cross flow.

Parallel and counter flow patterns are both in line flow patterns: two fluid streams flow in the same direction or in the opposite directions.

Parallel

In this heat exchanger, two fluids enter the exchanger at the same end, and travel in parallel to one another in the same direction to the other side.

In this case, the two fluids enter the unit from the same end with a large temperature difference. As the fluids transfer heat from the hotter fluid to the cooler one, their temperatures start to approach one another.

Counter

Two fluids enter the unit from opposite directions and travel against one another. Because the cooler fluid exits at the end where the hot fluid enters the heat exchanger, the cooler fluid will approach the inlet temperature of the hot fluid.

Counter flow is the most efficient of the three types. In contrast to parallel flow, a counter flow heat exchanger can have the hottest cold fluid temperature greater than the coldest-hot fluid temperature.

Cross

Fluids travel perpendicular to one another through the exchanger, i.e., one fluid flows through tubes and the second fluid passes around the tubes at 90° angle. These units are usually found in applications where one of the fluids changes state.

An example is a steam system’s condenser, where the steam exiting the turbine enters the condenser shell side, and the cool water flowing in the tubes absorbs the heat from the steam, condensing it into water.