Alfa Laval WideGap Gasketed Heat Exchangers

Ideal for Fluids Containing up to 8% w/v Solids or Fibres of up to 12mm in Diameter

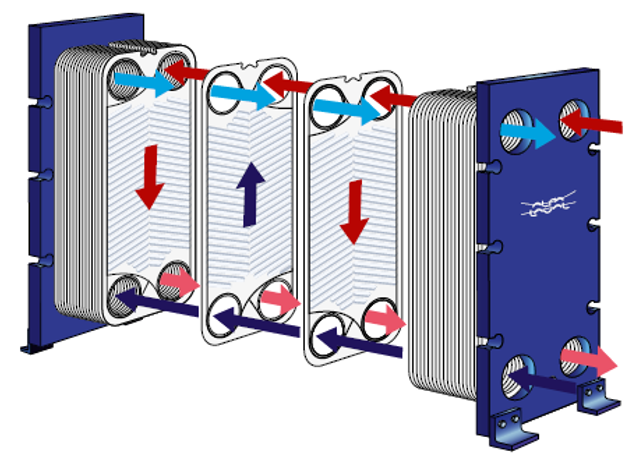

Alfa Laval WideGap units are suitable for all industrial applications where fluids are coarse or contain fibres, such as in the pulp & paper, bioethanol and sugar processing industries. The design of the plates allows for large particles in dirty fluids to pass through the system reducing issues related to fouling compared to traditional plate and frame or shell-and-tube heat exchangers. To extend uptime further, regular CIP (Cleaning in Place) flushing can be performed, taking advantage of small hold-up volumes to minimize chemical and water consumption.

In addition, high thermal efficiency and counter-current flow configurations help reduce energy consumption, and reduce the process footprint by up to 80% compared to a shell-and-tube unit.

Product Specifcations

See key applications, model comparisons, and options below:

|

Some key applications for WideGap units are detailed in the following table: |

||||

|---|---|---|---|---|

| Industry | Description | |||

| Ethanol | WideGap units are the perfect choice for fibrous raw materials like grain, cassava or cellulose. Cooling liquefied mash makes it possible to recover heat from any stream in the plant, helping reduce overall energy consumption. Likewise, when cooling fermented mash, no chilled water is necessary. |

|||

| Pulp & Paper | WideGap heat exchanger units can help recover and re-use far more energy from the industry’s warm, fibrous waste streams than conventional technologies. | |||

| Sugar | WideGap units are an excellent solution for raw juice and limed juice containing fibres; liquid, steam or low-pressure vapour can be used as heating media. | |||

| Petrochemicals | WideGap units are an ideal buy-and-forget solution as a pellet water cooler in petrochemical industries. They can also be used as a partial condenser to remove vapours from inerts, offering low pressure drop and more efficient subcooling of process media. |

|||

|

Some key applications for WideGap units are detailed in the following table: |

||||

|---|---|---|---|---|

| Industry | Description | |||

| Ethanol | WideGap units are the perfect choice for fibrous raw materials like grain, cassava or cellulose.

Cooling liquefied mash makes it possible to recover heat from any stream in the plant, |

|||

| Pulp & Paper | WideGap heat exchanger units can help recover and re-use far more energy from the industry’s warm, fibrous waste streams than conventional technologies. |

|||

| Sugar | WideGap units are an excellent solution for raw juice and limed juice containing fibres; liquid, steam or low-pressure vapour can be used as heating media. |

|||

| Petrochemicals | WideGap units are an ideal buy-and-forget solution as a pellet water cooler in petrochemical industries. They can also be used as a partial condenser to remove vapours from inerts, offering low pressure drop and more efficient subcooling of process media. |

|||

WideGap units are also ideal for the condensation of low-pressure process vapours; wider channels allow for low pressure drop on the vapour side to reduce wasted process energy.

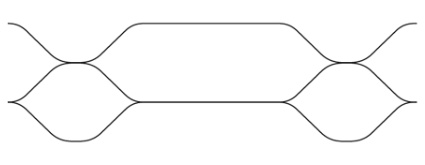

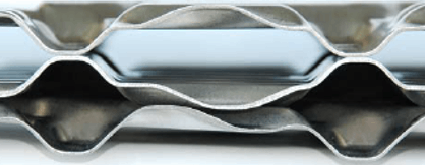

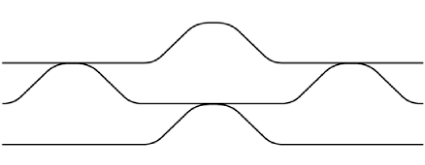

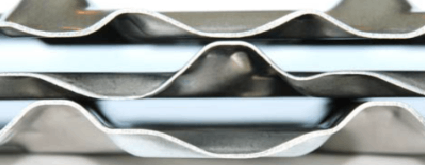

Configurations with wide-narrow or wide-wide channels are available for heating, cooling and interchanging duties:

Wide-narrow configuration for system with one non-fibrous fluid.

Wide-wide configuration for system without non-fibrous fluids.

WideGap Heat Exchanger Models

| WideGap Model | 100S | 200S | 350S | 350X | MA30-S | MA30-S/M | |

|---|---|---|---|---|---|---|---|

| Max Design Temp. in °F (°C) | 320 (160) | 320 (160) | 356 (180) | 293 (145) | 284 (140) | 266 (130) | |

| Max Design Pressure in psi (bar) | 160 (11) | ||||||

| Port Diameter in inches | 4″ | 8″ | 14″ | 14″ | 12″ | 12″ | |

| Free Channel (average plate gap) in mm |

Wide-Narrow | 11 & 5 | 11 & 5 | 11 & 5 | 18 & 5 | 11 & 5 | |

| Wide-Wide | 8 | 8 | 8 | 11 | 11 | ||

The following plate materials are available:

- Alloy 316

- Alloy 254

- Titanium

The following gasket materials are available:

- NBR

- EPDR

- FKM (Viton®)

In addition, the following gasket types are available:

- ClipGrip™

- Glue