Alfa Laval Welded Heat Exchangers

Product Range

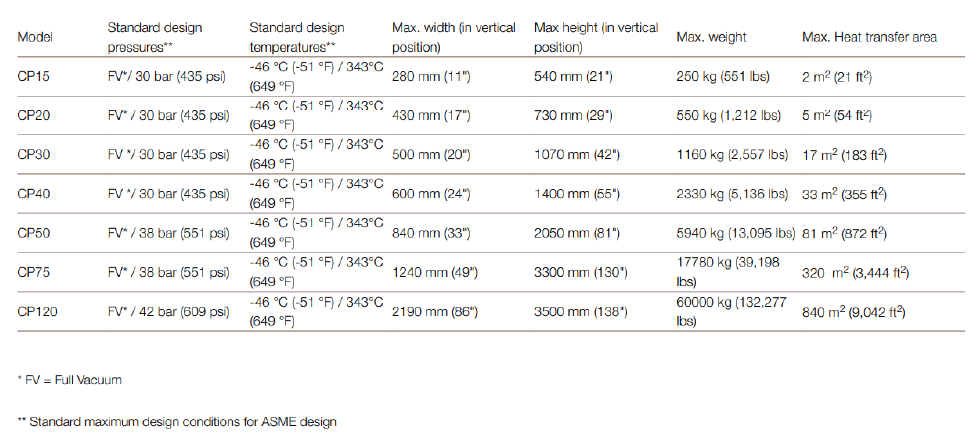

Alfa Laval Compabloc® consists of heat transfer plates that are welded alternatively to form channels and uses no gaskets. The standard design temperature ranges from -100°C to 350°C with standard pressure ranging up to 42bar. It is available in virtually any material that can be pressed and welded, including but not limited to 316L, 254SMO, Titanium grade 1, 904L, Alloy C276 and Alloy C22. The laser-welded range of Compabloc® is available with five plate patterns:

- K series = designed for efficient mechanical cleaning – CPK40, CPK50 & CPK75

- L series = for high-pressure applications – CPL30, CPL50 & CPL75

- X series = combining high pressure and mechanical cleaning ability – CPX120

- H series = hygienic design – HCP15, HCP20, HCP30 & HCP40

- M series = 2 section condensers with 2 different cooling media – CPM15, CPM20 & CPM30

The table above provides some inputs for the standard range. (Other conditions are available on request)

Advantages

The payback time of a Compabloc® is very short, normally within a matter of months. The Compabloc® saves money due to its high thermal efficiency and high heat recovery which makes it possible to save fuel consumption. In addition to that, with increased focus on environmental factors to reduce emissions, it allows the customer to save energy which relates directly into savings on CO2 emissions.

1MW saved/year = 970 tons of fuel = 2500 less tons of CO2 to the atmosphere

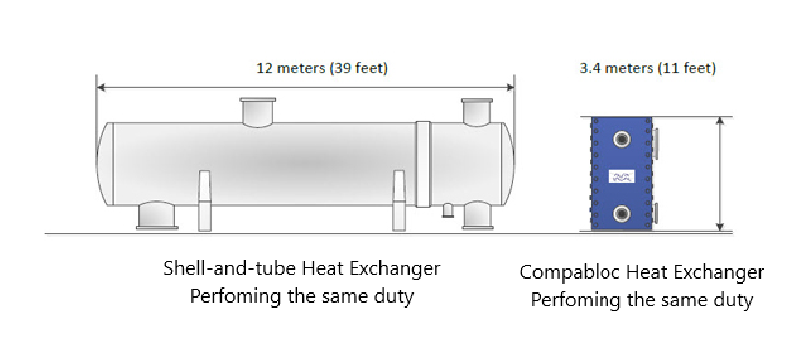

Fully welded and easily accessible for inspection, service, or cleaning. No gasket between the plates allows handling of aggressive media at high temperatures and pressures. The corrugated plates minimize fouling which makes longer operating periods possible. Can be used for close temperature approaches down to 3° C (5.4°F). It takes only fraction of the floor space when compared to a shell-and-tube heat exchanger. Low capital and installation cost.

C-Weld™

End-to-end laser weld of the plates guarantees accessibility and protects against corrosion.

SmartClean™

Free-flow channel at all plate boundaries secures efficient removal of fouling.

XCore™

A high-pressure, cleanable plate pattern that increases mechanical strength to improve thermal performance.

ALOnsite™

True onsite service by skilled engineers, anywhere in the world.

Three ways to install the Compabloc®

Vertical Mounting

Normally used for liquid-to-liquid duties, condensation with subcooling and gas cooling duties, particularly when floor space is limited.

Horizontal Mounting

Used for condensation duties, re-boiling, gas cooling or liquid-to-liquid duties when there are height limitations.

Suspended Mounting

Used for condensation duties, re-boiling, gas cooling or liquid-to-liquid duties when there are height limitations.

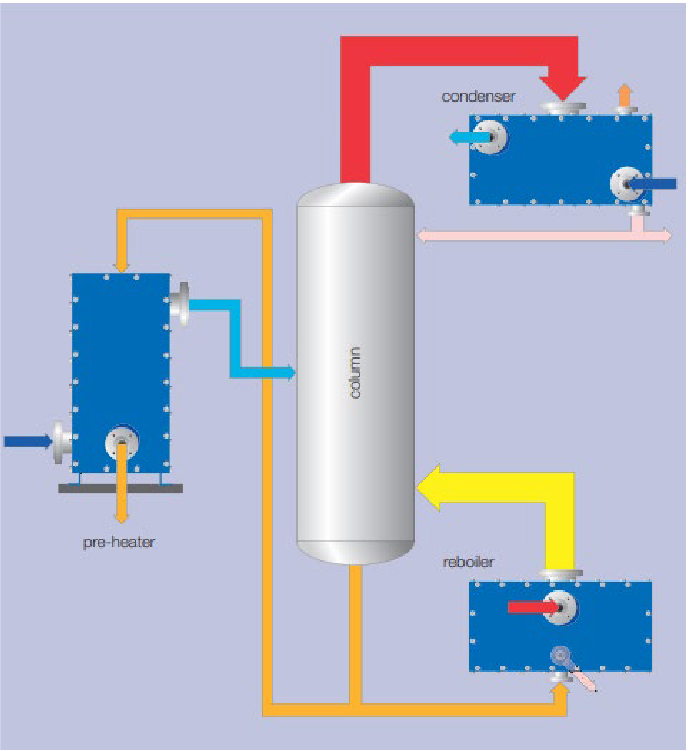

Compabloc® is a perfect choice for challenging reboilers, condenser and liquid-to-liquid heat exchanger duties inchemical, petrochemical, oil and gas, and refineries. The Compabloc® can be virtually installed anywhere – as a condenser on top of reactors or reboilers for distillation and stripping columns.

In condensing and evaporating duties, the Compabloc® provides additional advantage. It does not require any extra equipment. A two-pass arrangement on the condensing side permits gas-liquid separation in the unit, thereby eliminating the need for a separator.

Product Composition

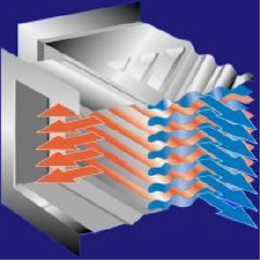

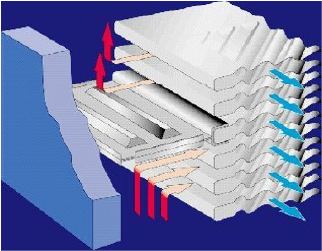

Alfa Laval Compabloc® consists of heat transfer plates that are welded alternatively to form channels and uses no gaskets. It is designed for a wide range of process and utility duties but are ideal for handling high temperature and pressure applications. The Compabloc® provides the most efficient, cost-effective, compact, and cleanable heat exchanger solution. The design is based on breakthrough technology which consists of plates that are laser welded to form baffles. These baffles can be arranged to form either crossflow or counter-current flow. The baffles are then stacked in a steel bolted frame for easy access on all side.

Heat Transfer Plate

Plates laser welded to form a plate pack

Steel Bolted Frame

Plate pack in the steel bolted frame

Crossflow

Steel Bolted Frame

Maintenance

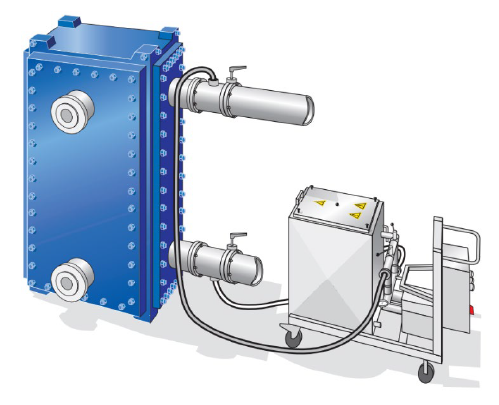

In a shell-and-tube installation, the tube bundle needs to be replaced periodically and requires to be pulled out axially. This means considerable extra space is needed for maintenance, space that should be kept free for all other equipment. The unique design of the Compabloc® helps simplify servicing. The high shear rate ensures seldom fouling problems. The high turbulence allows it to make chemical cleaning in place (CIP) both effective and economical. The side panels can be easily removed for visual inspection and high-pressure wash cleaning. Due to its easy accessibility the visual inspection takes less time which cuts downtime. The plate pack can also be disassembled and immersed in chemical for cleaning

On site cleaning inplace performed by circulating solutions through the Compabloc®

Easy access for hydro jet cleaning up to 1000 bar

Application

- Oil & gas production

- Refineries

- Hydrocarbon process industry

- Pharmaceutical industry & specialty chemicals

- Coke oven plants

- Chlorine alkali plants

- Fertilizer production

- Hydrogen peroxide plants

- Ammonium nitrate

- Mining industry

- HVAC, district heating, energy, utilities, general services