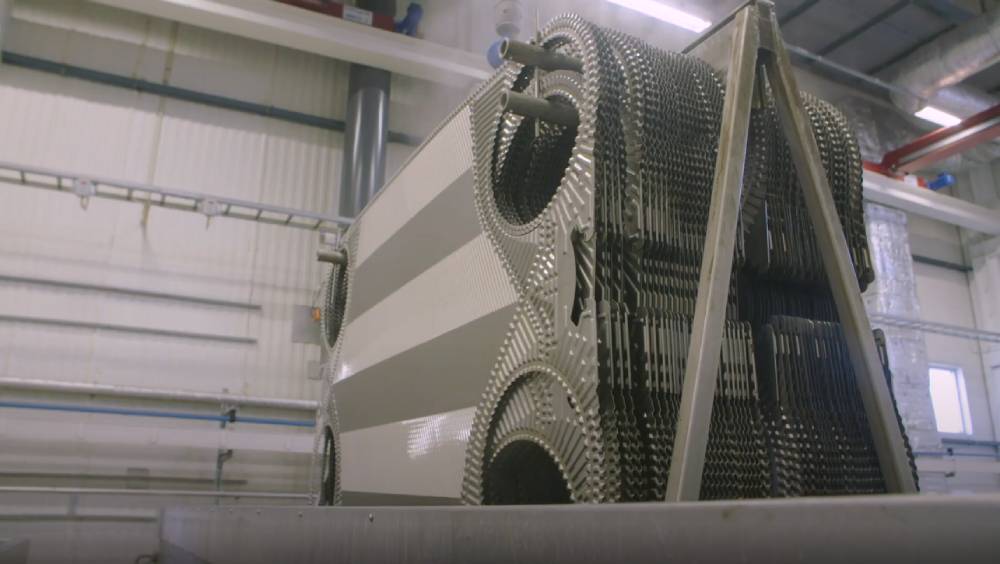

Plate Heat Exchanger Repair

Reconditioning and Repair to Extend Heat Exchanger Lifespan

Valutech offers comprehensive repair and reconditioning of your plate heat exchanger at Alfa Laval’s state-of-the-art ISO 900 facility in Scarborough, Ontario. We offer servicing and re-gasketing for all Alfa Laval (Vicarb) and Tranter makes and models, as well as APV, Armstrong, ITT, Sondex, Swep, Polaris, GEA, and Schmidt-Bretten units.

Valutech’s reconditioning procedures are specifically tailored to clean and service your unit’s components, while simultaneously retaining the integrity of the plates. With plate heat exchangers tending to foul between plates and corroding within the plate grooves, proper reconditioning requires gentle removal of gaskets to avoid damaging the plates. To this end, Valutech is the only company in Canada to use liquid nitrogen processing in the gasket removal process to ensure no damage is done to the plates. For more information on our process, please see the detailed explanation below:

Our Repair and Reconditioning Process

Unit Arrival & Initial Inspection

Upon arrival at our service center, your units will undergo an inspection to identify both imminent and emerging problems that our technicians will address during the repair and reconditioning process.

Gasket Removal

The plates are dipped in a liquid nitrogen bath at -196°C (-320°F), allowing the glued-on gaskets to be removed gently and effectively without stripping or damaging the plates, while avoiding issues that arise from residual glue.

This one-of-a-kind process in Canada ensures that no damage occurs to the plates by way of physical chiseling of the gaskets, or the use of harmful chemicals.

Plate Cleaning

After a clean separation of the gaskets, the plates are then dipped into a series of intensive chemical baths that are either alkaline or acidic.

This process is carried out under the supervision of certified technicians to ensure ideal chemical balance of the solution.

Dye Inspection & Deformation Test

Following the chemical cleaning process, the plates are run through several tests designed to identify a variety of instability issues, such as cracks and pinhole leaks.

During this part of the inspection, the plates are sprayed with dye penetrants and are observed under UV lighting, allowing us to determine the number of defective plates to be replaced.

In addition, measurements are made to determine the level of plate deformation; plates that are deformed beyond an acceptable level are marked as defective. Upon passing all inspections, the plates are then pressure washed to remove all traces of the dye coating.

For more information on the benefits of the process,

please see the following video:

Professional On-Site Service

Valutech offers professional turnkey servicing of your heat exchanger, performed by factory-trained Alfa Laval technicians.

We can open, clean, remove plate packs, re-gasket, re-install plate packs, re-tighten, and close your unit on-site, while ensuring the utmost reliability and safety.

Not the service that you’re looking for?

Click here to see the other services we offer.