Heat Exchanger Plates

Maintain and Upscale Your Units with Our Extensive Offering of Heat Exchanger Plates

Valutech offers a comprehensive selection of plates to replace your current set or to upscale your plate heat exchangers; we supply Alfa Laval (Vicarb), Tranter, APV, GPX, and V-Series models, and stock the following Alfa Laval plates at our facility in Scarborough, Ontario:

Alfa Laval M-Series

- M3

- M3-X

- M3-D

- M3-FG

- M6

- M6-B

- M6-FD

- M6-D

- M6-FG

- M6-M

- M6-MD

- M6-MFD

- M6-MFG

- M10

- M10-M

- M10-B

- M10-BD

- M10-BFD

- M10-BFG

- M10-MFM

- M10-MFD

- M10-MFG

- M15

- M15-M

- M15-B

- M15-BD

- M15-BFD

- M15-BFG

- M15-MFD

- M15-MFG

- M15-MFM

Alfa Laval T-Series

- T5-B

- T5-P

- T6-P

- T6-B

- TS6

- TS6-M

- TL6

- TL6-B

- T10-B

- T10-M

- TL10

- TL10-B

- TL10-P

When you need plates right away, Valutech is prepared to assist you at virtually any time; all of the plates listed above can be picked up after business hours and on weekends, as well as during normal operating hours. In an emergency situation, count on us to help ensure process downtime is minimized and plate-related issues are dealt with as quickly as possible.

Heat Exchanger Plates

Browse our wide selection of plate brands and models.

For a comprehensive list of all the gaskets we supply, please see the following lists below.

For a specific brand of plate, please select from the following list:

Plates for Alfa Laval Heat Exchangers

Alfa Laval M-Series

- M3

- M3-X

- M3-D

- M3-FG

- M6

- M6-B

- M6-FD

- M6-D

- M6-FG

- M6-M

- M6-MD

- M6-MFD

- M6-MFG

- M10

- M10-M

- M10-B

- M10-BD

- M10-BFD

- M10-BFG

- M10-MFM

- M10-MFD

- M10-MFG

- M15

- M15-M

- M15-B

- M15-BD

- M15-BFD

- M15-BFG

- M15-MFD

- M15-MFG

- M15-MFM

- M20-M

- M20-MFD

- M20-MFG

- M20-MFM

- MX25-B

- MX25B-FD

- MX25B-FG

- MX25B-FS

- MX25-M

- MX25M-FD

- M30

- M30-D

- M30-FD

- M30-FG

Alfa Laval T-Series

- T5-B

- T5-P

- T6-P

- T6-B

- TS6

- TS6-M

- TL6

- TL6-B

- T10-B

- T10-M

- TL10

- TL10-B

- TL10-P

- T20-B

- T20-M

- T20-BW

- T20-P

- TS20-M

- T20-MW

Alfa Laval A-Series*

- A3

- A10

- A10-B

- AM10

- A10-B

- A15

- A15-B

- A20

- A20-B

- AK20

- AM20

- AM20-B

- AM20-N

- AM20-S

- AM20-W

- A30

- AX30

- AX30-B

*Alfa Laval A-Series units are obsolete; however, if you would like to purchase replacement plates for this series, please contact us for assistance.

Alfa Laval P-Series

- P01

- P02

- P5

- P5-1

- P5-2

- P5-3

- P5-4

- P12

- P12-2

- P12-4

- P13

- P13-2

- P13-5

- P14

- P14/LI

- P14-5

- P15

- P16

- P17

- P20

- P25

- P26

- P30

- P31

- P32

- P36

- P41

- P45

- P225

Alfa Laval ClipLine

- Clip 3

- Clip 3-RH

- Clip 6

- Clip 6-RH

- Clip 8

- Clip 8-RH

- Clip 10

- Clip 10-RH

Alfa Laval Welded

- A15-BW

- AM20-BW

- AX30-BW

- M6-MW

- M10-BW

- MK15-BW

- M20-MW

- MA30-W

- EC-500

Misc. Alfa Laval Models

- H7

- H10

- JWP26

- JWP36

- MS6

- MS10

- MS15

- M30-M

- MA30-S

Plates for GPX Heat Exchangers

GPX

- GPX-4A

- GPX-7A

- GPX-8AA

- GPX-20A

- GPX-258B

- GPX-538B

- GPX-850B

- GPX-15

- GPX-20

- GPX-22

- GPX-30

- GPX-34

- GPX-35

- GPX-37

- GPX-38

- GPX-39

- GPX-43

- GPX-47

- GPX-50

- GPX-62

- GPX-65

- GPX-100

- GPX-120

- GPX-130

- GPX-151

- GPX-161

- GPX-237

- GPX-258

- GPX-463

- GPX-538

- GPX-646

- GPX-678

- GPX-807

- GPX-840

- GPX-915

- GPX-1152

- GPX-1614

- GPX-1700

- GPX-1980

- GPX-2150

- GPX-3910

Plates for APV Heat Exchangers

APV SR

- SR1

- SR2

- SR3

- SR6-AA

- SR6-AG

- SR6-GH

- SR6-GL

- SD9

- SR9

- SR14-AD

- SR14-AH

- SR14-AN

- SR14-AP

- SR14-GD

- SR15-PE

- SR23-AO

- SR23-PV

- SR23-VO

APV R

- R5

- ER5

- R40

- R40-5

- R6

- R6-6

- R8-AH

- R8-GI

- R10

- R10-6

- R86

- R89

APV B

- B063-L

- B063-S

- B110-L

- B110-S

- B134-L

- B134-S

- B158-L

- B158-S

- B205-L

- B205-S

APV J

- J060

- J092

- J107

- J185

APV QD/QE

- QD030

- QD055

- QD080

- QE055

- QE080

APV TR

- TR1

- TR9-AL

- TR9-AV

- TR9-GL

- TR9-GN

APV LR/LD

- LR9-AL

- LR9-GL

- LR9-GN

- LD9-AL

- LD9-GL

- LD9-GN

APV Pasilac

- T4

- R55

- D37

- K34

- K55

- K71

- H12

- H17

- N25

- N35

- N50

- M60

- M92

- M107

- M185

Misc. APV Models

- R

- WHX

- HM-B

- P105

- P190

- A055

- A085

- CHF130

- FFP-E

- RFF

- SER III

- RFF-PE

- U2

Plates for Tranter Heat Exchangers

Tranter UX

- UX01

- UX015

- UX016

- UX025

- UX026

- UX095

- UX096

- UX05

- UX06

- UX056

- UX058

- UX066

- UX068

- UX076

- UX078

- UX10

- UX115

- UX116

- UX125

- UX126

- UX195

- UX196

- UX215

- UX216

- UX225

- UX226

- UX295

- UX40

- UX415

- UX416

- UX418

- UX425

- UX426

- UX428

- UX495

- UX496

- UX498

- UX80

- UX81

- UX83

- UX815

- UX816

- UX818

- UX825

- UX826

- UX828

- UX836

- UX838

- UX846

- UX848

- UX886

- UX888

- UX895

- UX896

- UX898

- 06-T

- 06-T16

- 06-T18

- 06-T10

- 06-T26

- 06-T28

- 06-T20

- 06-T96

- 06-T98

- 06-T90

- 11T

Tranter UFX (with Re-heat)

- UFX6

- UFX12

- UFX18

- UFX26

- UFX37

- UFX42

- UFX51

- UFX60

- UFX64

- UFX85

- UFX91

- UFX100

- UFX118

- UFX140

- UFX145

- UFX180

- UFX205

- GX85

- GX91

- GX100

- GX118

- GX140

- GX145

- GX180

- GX205

Tranter S

- S3

- S8

Tranter TW/TD

- TW05

- TW10

- TW18

- TD10

Tranter GM/GB

- GM138

- GB257

- GM276

- GM56

- GM59

Tranter GX

- GX6

- GX12

- GX18

- GX26

- GX37

- GX42

- GX48

- GX51

- GX60

- GX64

- GX85

- GX91

- GX100

Tranter UXP

- UXP005

- UXP010

- UXP060

- UXP100

- UXP110

- UXP200

- UXP400

- UXP801

- UXP900

- UXP960

Tranter GCD/GCP

- GCD006

- GCD012

- GCD030

- GCD054

- GCD055

- GCD065

- GCP026

- GCP030

- GCP051

- GCP060

Tranter GXP/GF

- GXP018

- GXP026

- GXP037

- GXP042

- GXP051

- GXP118

- GF057

- GF097

- GF187

Tranter GXD

- GXD012

- GXD018

- GXD026

- GXD037

- GXD042

- GXD051

- GXD060

- GXD064

- GXD085

- GXD091

- GXD100

- GXD140

- GXD145

- GXD180

Tranter HX

- HX12

- HX25

- HX50

- HX85

- HX180

Tranter GFP/GLD/GLP

- GFP030

- GFP050

- GFP057

- GFP080

- GFP097

- GFP100

- GFP180

- GFP187

- GLD013

- GLP013

Tranter HXD/HXP

- HXD012

- HXD025

- HXD050

- HXD085

- HXD145

- HXD180

- HXP050

Plates for V-Series Heat Exchangers

V-Series Double Wall

- V4-DW

- V13-DW

- V20-DW

- V45-DW

- V60-DW

V-Series Clip-On/Glue/Ball

- V4

- V7

- V8

- VU8

- VU12

- V13

- V20

- V28

- V45

- V55

- V60

- V85

- V100

- V100 RT

- V120

- V130

- V180

- V260

Can’t find the plates that you’re looking for?

Valutech also offers additional plates and competitor models for more specific applications; contact us today to find the ideal plates for your process.

For further assistance in choosing the ideal plates for your process,

please see the following explanations regarding the various materials and plate structures available:

Why Choose Alfa Laval Plates?

Alfa Laval heat exchanger plates feature a number of design features that promote extended, high-performance operation for longer periods compared with their competitors’ plate designs. The advantages of Alfa Laval plates in 8 categories were demonstrated in a case study by accredited laboratory Swedac; the following is a summary of the results in each category:

Plate Pattern

Alfa Laval plate patterns offer optimized, even fluid

distribution and increased heat transfer efficiency compared to “W” patterns, or different plate angles.

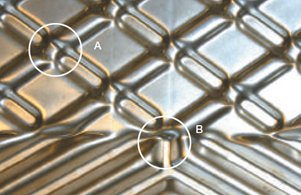

Note the edge design of the Alfa Laval plate (left) with respect to the non-Alfa Laval equivalent with a crack (right).

Alfa Laval Plate Edge Design

Non-Alfa Laval Plate Edge Design

Plate Distribution Area

Alfa Laval plate patterns also offer distinct patterns for increased mechanical stability, as well as reduced fouling, and leakage due pressure fluctuations.

They achieve this with a distinct pattern in the transition area between heat transfer and distribution spaces.

Pressed pattern (A) for stability at high pressures; pressed pattern (B) for

fatigue resistance.

Comparatively weaker designs at (A) and (B) lead to plate deformation at high pressure, and fatigue, respectively.

Pressing Depth

Competitor plates suffer from uneven pressing depths and low surface quality due to lower material quality; these issues can readily lead to metal fatigue and gasket blowout.

Portholes

Competitor plates suffer from off-centre, incorrectly sized portholes; this can lead to the plate pivoting and the gasket coming loose. Porthole inconsistencies also reduce heat transfer efficiency and lead to fatigue cracking.

Gasket Groove

Alfa Laval plates offer stronger groove shapes,

reducing the risks of gasket blowout and stress concentration in the vicinity of portholes; increases overall gasket lifetime.

Carrying Bar-Plate Interface

Alfa Laval carrying bar-plate interfaces feature a unique tube design to support the weight of the plates; competitor models suffer from a design that allows plates to slide relative to their supports during mounting/de-mounting.

Alfa Laval gasket groove design.

Inferior gasket groove design and incorrectly–shaped carrying bar–plate interface leading to scratching.

Corner Guides

Alfa Laval plates offer distinctly-shaped corners for secure fastening and optimal alignment. Inferior corner guide designs lead to snaking, misalignment, sliding of plates, and gasket blowout.

Gasket Attachment

The gasket attachments in Alfa Laval plates are located optimally to improve media flow and mechanical properties of the plate, as well as reduce stress concentration near the holes that would otherwise weaken plates.

Material Varieties

Valutech specialists are available to assist you in finding the plate with ideal parameters to match your process, including plates that can withstand certain process conditions and media. The following is a brief list of possible plate materials, and their applications:

Stainless Steel: Valutech carries SS304 and SS316 plates for virtually all available models. Stainless steel is a staple among heat exchanger plate materials, and is often chosen for its ability to withstand high temperatures, as well as its mechanical strength and corrosion resistance.

Stainless steel plates are a relatively economical choice, with a wide variety of fabrication options and are generally in high supply; they are also easy to clean and stand up to a large number of cleaning cycles. The use of stainless steel also helps with the reduction of limestone deposits and other residues.

Titanium: Another commonly-used material within plate heat exchangers, it offers a high strength:weight ratio and higher corrosion resistance compared to stainless steel. Titanium is supplied in a number of grades, where grades 1-4 are considered commercially pure, and typically used in heat exchangers.

In addition to these materials, Valutech supplies other alloys for more specific applications, such as those with a greater risk of corrosion.

The following list includes some of the alloys that are also available:

- Alloy 254

- Alloy C276

- Alloy C2000

- Alloy 904L

- Alloy G30

- Alloy C276

- TiPd

If there is another material that you would like to inquire about, please contact Valutech to discuss it with one of our experts.

Structure

For a given plate material, a plate heat exchanger can have a number of construction styles depending on the application and desired treatment of process media. A benefit of gasketed plate heat exchangers is not only that plates can be replaced on a per plate basis, but standard models can have plates added up to a certain capacity limit; this means that upscaling of your process can be performed by purchasing plates for your existing unit, rather than purchasing a new unit altogether.

Generally, plates are designed to counter-act a fluid’s tendency to take the path of least resistance through it, maximizing the fluid’s ability to stick to a single surface, utilizing as much of the unit’s surface area as possible to maximize heat transfer. The following construction styles are just two examples of possible plate heat exchanger structures:

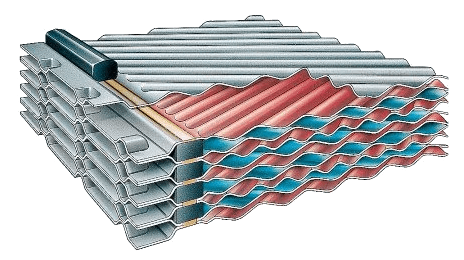

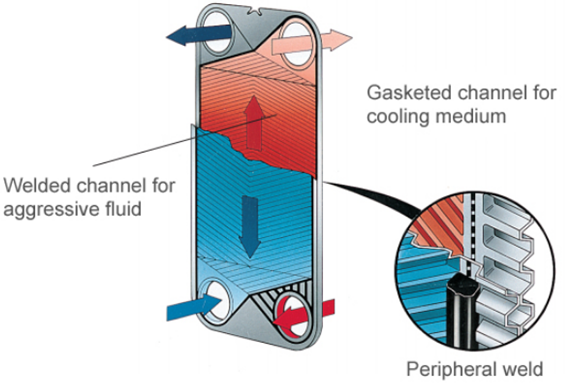

Semi-welded: Where a traditional plate-and-frame heat exchanger is sealed entirely with gaskets, a semi-welded construction alternates between laser welds and gaskets. The laser-welded channel is suitable for long-term operation using process media that would not be compatible with standard gaskets. In addition, this construction allows for higher design pressures.

Double-Wall: Similar to a traditional heat exchanger, where channels are conventional and sealed by gaskets in a traditional manner; the key difference is that single plates are replaced by two-plate pairs welded together around the portholes. This allows for one of the process media streams to appear externally in the case of a leak, regardless of whether the issue is with a plate or a gasket. If it is imperative that process fluids do not mix, a double wall model is the ideal choice of heat exchanger.

Not the service that you’re looking for?

Click here to see the other services we offer.