Plate Heat Exchanger Gaskets

Extend Heat Exchanger Lifespan with Our Extensive Selection of Gaskets

Valutech offers a comprehensive selection of replacement gaskets for your plate heat exchangers. We supply Alfa Laval, AGC, API Schmidt-Bretten, APV (SPX), Armstrong, GEA, Muller, Sondex, Thermaline, Tranter, and Vicarb. We stock the following Alfa Laval gaskets at our facility in Toronto, Ontario:

Alfa Laval M-Series

- M3

- M3-X

- M3-D

- M3-FG

- M6

- M6-B

- M6-FD

- M6-D

- M6-FG

- M6-M

- M6-MD

- M6-MFD

- M6-MFG

- M10

- M10-M

- M10-B

- M10-BD

- M10-BFD

- M10-BFG

- M10-MFM

- M10-MFD

- M10-MFG

- M15

- M15-M

- M15-B

- M15-BD

- M15-BFD

- M15-BFG

- M15-MFD

- M15-MFG

- M15-MFM

Alfa Laval T-Series

- T5-B

- T5-P

- T6-P

- T6-B

- TS6

- TS6-M

- TL6

- TL6-B

- T10-B

- T10-M

- TL10

- TL10-B

- TL10-P

When you need gaskets right away, Valutech is prepared to assist you at virtually any time; all of the gaskets listed above can be picked up after business hours and on weekends, as well as during normal operating hours. In an emergency situation, count on us to help ensure process downtime is minimized and gasket-related failures are dealt with as quickly as possible.

Replacement Gaskets

Browse our wide selection of gasket brands and models.

For a comprehensive list of all the gaskets we supply, please see the following lists below. Contact us today to order your replacement gaskets.

For a specific brand of gasket, please select from the following list:

Replacement Gaskets for Alfa Laval Heat Exchangers

Alfa Laval M-Series

- M3

- M3-X

- M3-D

- M3-FG

- M6

- M6-B

- M6-FD

- M6-D

- M6-FG

- M6-M

- M6-MD

- M6-MFD

- M6-MFG

- M10

- M10-M

- M10-B

- M10-BD

- M10-BFD

- M10-BFG

- M10-MFM

- M10-MFD

- M10-MFG

- M15

- M15-M

- M15-B

- M15-BD

- M15-BFD

- M15-BFG

- M15-MFD

- M15-MFG

- M15-MFM

- M20-M

- M20-MFD

- M20-MFG

- M20-MFM

- MX25-B

- MX25B-FD

- MX25B-FG

- MX25B-FS

- MX25-M

- MX25M-FD

- M30

- M30-D

- M30-FD

- M30-FG

Alfa Laval T-Series

- T5-B

- T5-P

- T6-P

- T6-B

- TS6

- TS6-M

- TL6

- TL6-B

- T10-B

- T10-M

- TL10

- TL10-B

- TL10-P

- T20-B

- T20-M

- T20-BW

- T20-P

- TS20-M

- T20-MW

Alfa Laval A-Series

- A3

- A10

- A10-B

- AM10

- A10-B

- A15

- A15-B

- A20

- A20-B

- AK20

- AM20

- AM20-B

- AM20-N

- AM20-S

- AM20-W

- A30

- AX30

- AX30-B

Alfa Laval P-Series

- P01

- P02

- P5

- P5-1

- P5-2

- P5-3

- P5-4

- P12

- P12-2

- P12-4

- P13

- P13-2

- P13-5

- P14

- P14/LI

- P14-5

- P15

- P16

- P17

- P20

- P25

- P26

- P30

- P31

- P32

- P36

- P41

- P45

- P225

Alfa Laval ClipLine

- Clip 3

- Clip 3-RH

- Clip 6

- Clip 6-RH

- Clip 8

- Clip 8-RH

- Clip 10

- Clip 10-RH

Alfa Laval Welded

- A15-BW

- AM20-BW

- AX30-BW

- M6-MW

- M10-BW

- MK15-BW

- M20-MW

- MA30-W

- EC-500

Misc. Alfa Laval Models

- H7

- H10

- JWP26

- JWP36

- MS6

- MS10

- MS15

- M30-M

- MA30-S

Replacement Gaskets for GPX Heat Exchangers

GPX

- GPX-4A

- GPX-7A

- GPX-8AA

- GPX-20A

- GPX-258B

- GPX-538B

- GPX-850B

- GPX-15

- GPX-20

- GPX-22

- GPX-30

- GPX-34

- GPX-35

- GPX-37

- GPX-38

- GPX-39

- GPX-43

- GPX-47

- GPX-50

- GPX-62

- GPX-65

- GPX-100

- GPX-120

- GPX-130

- GPX-151

- GPX-161

- GPX-237

- GPX-258

- GPX-463

- GPX-538

- GPX-646

- GPX-678

- GPX-807

- GPX-840

- GPX-915

- GPX-1152

- GPX-1614

- GPX-1700

- GPX-1980

- GPX-2150

- GPX-3910

Replacement Gaskets for APV Heat Exchangers

APV SR

- SR1

- SR2

- SR3

- SR6-AA

- SR6-AG

- SR6-GH

- SR6-GL

- SD9

- SR9

- SR14-AD

- SR14-AH

- SR14-AN

- SR14-AP

- SR14-GD

- SR15-PE

- SR23-AO

- SR23-PV

- SR23-VO

APV R

- R5

- ER5

- R40

- R40-5

- R6

- R6-6

- R8-AH

- R8-GI

- R10

- R10-6

- R86

- R89

APV B

- B063-L

- B063-S

- B110-L

- B110-S

- B134-L

- B134-S

- B158-L

- B158-S

- B205-L

- B205-S

APV J

- J060

- J092

- J107

- J185

APV QD/QE

- QD030

- QD055

- QD080

- QE055

- QE080

APV TR

- TR1

- TR9-AL

- TR9-AV

- TR9-GL

- TR9-GN

APV LR/LD

- LR9-AL

- LR9-GL

- LR9-GN

- LD9-AL

- LD9-GL

- LD9-GN

APV Pasilac

- T4

- R55

- D37

- K34

- K55

- K71

- H12

- H17

- N25

- N35

- N50

- M60

- M92

- M107

- M185

Misc. APV Models

- R

- WHX

- HM-B

- P105

- P190

- A055

- A085

- CHF130

- FFP-E

- RFF

- SER III

- RFF-PE

- U2

Replacement Gaskets for Tranter Heat Exchangers

Tranter UX

- UX01

- UX015

- UX016

- UX025

- UX026

- UX095

- UX096

- UX05

- UX06

- UX056

- UX058

- UX066

- UX068

- UX076

- UX078

- UX10

- UX115

- UX116

- UX125

- UX126

- UX195

- UX196

- UX215

- UX216

- UX225

- UX226

- UX295

- UX40

- UX415

- UX416

- UX418

- UX425

- UX426

- UX428

- UX495

- UX496

- UX498

- UX80

- UX81

- UX83

- UX815

- UX816

- UX818

- UX825

- UX826

- UX828

- UX836

- UX838

- UX846

- UX848

- UX886

- UX888

- UX895

- UX896

- UX898

- 06-T

- 06-T16

- 06-T18

- 06-T10

- 06-T26

- 06-T28

- 06-T20

- 06-T96

- 06-T98

- 06-T90

- 11T

Tranter UFX (with Re-heat)

- UFX6

- UFX12

- UFX18

- UFX26

- UFX37

- UFX42

- UFX51

- UFX60

- UFX64

- UFX85

- UFX91

- UFX100

- UFX118

- UFX140

- UFX145

- UFX180

- UFX205

- GX85

- GX91

- GX100

- GX118

- GX140

- GX145

- GX180

- GX205

Tranter S

- S3

- S8

Tranter TW/TD

- TW05

- TW10

- TW18

- TD10

Tranter GM/GB

- GM138

- GB257

- GM276

- GM56

- GM59

Tranter GX

- GX6

- GX12

- GX18

- GX26

- GX37

- GX42

- GX48

- GX51

- GX60

- GX64

- GX85

- GX91

- GX100

Tranter UXP

- UXP005

- UXP010

- UXP060

- UXP100

- UXP110

- UXP200

- UXP400

- UXP801

- UXP900

- UXP960

Tranter GCD/GCP

- GCD006

- GCD012

- GCD030

- GCD054

- GCD055

- GCD065

- GCP026

- GCP030

- GCP051

- GCP060

Tranter GXP/GF

- GXP018

- GXP026

- GXP037

- GXP042

- GXP051

- GXP118

- GF057

- GF097

- GF187

Tranter GXD

- GXD012

- GXD018

- GXD026

- GXD037

- GXD042

- GXD051

- GXD060

- GXD064

- GXD085

- GXD091

- GXD100

- GXD140

- GXD145

- GXD180

Tranter HX

- HX12

- HX25

- HX50

- HX85

- HX180

Tranter GFP/GLD/GLP

- GFP030

- GFP050

- GFP057

- GFP080

- GFP097

- GFP100

- GFP180

- GFP187

- GLD013

- GLP013

Tranter HXD/HXP

- HXD012

- HXD025

- HXD050

- HXD085

- HXD145

- HXD180

- HXP050

Replacement Gaskets for Vicarb Heat Exchangers

Vicarb Double Wall

- V4-DW

- V13-DW

- V20-DW

- V45-DW

- V60-DW

Vicarb Clip-On/Glue/Ball

- V4

- V7

- V8

- VU8

- VU12

- V13

- V20

- V28

- V45

- V55

- V60

- V85

- V100

- V100 RT

- V120

- V130

- V180

- V260

Can’t find the gasket that you’re looking for?

Valutech also offers additional gaskets for more specific applications; contact us today to find the ideal gasket for your process.

For further assistance in choosing the ideal gasket for your process, please see the following explanations regarding the various materials, structures, and composition of the gaskets available, as well as the research and manufacturing processes that go into making them.

Material Varieties

Valutech specialists are available to assist you in finding the gasket with ideal composition and parameters to match your process, including gaskets that can withstand certain temperatures and pressures, as well as certain process media.

The following is a brief list of possible gasket materials, and their applications:

NBR

Able to withstand temperatures of up to 138°C (280°F), NBR gaskets are ideal for use in processes with oil-containing media due to its polar nature, as well as water-to-water applications in non-process related duties, such as heat recovery and potable water applications.

EPDM

The non-polar nature of EPDM gaskets allows them to resist water and steam, as well as acidic, saline, and alkaline solutions. They are generally used in water-to-water applications, and are able to withstand temperatures of up to 180°C (356°F).

FKM

Originally made under the Viton® name, the two varieties of FKM gaskets are known as FKMT and FKMG. They are generally utilized in high-temperature, steam-based applications, and can be used in conjunction with stainless steel and titanium plates with process media of temperatures up to 204°C (400°F), and 100°C (212°F), respectively.

Material Advantages & Limitations

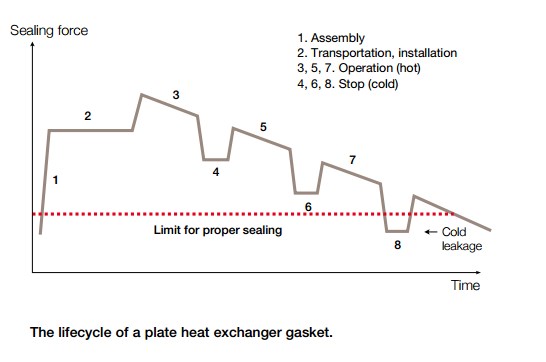

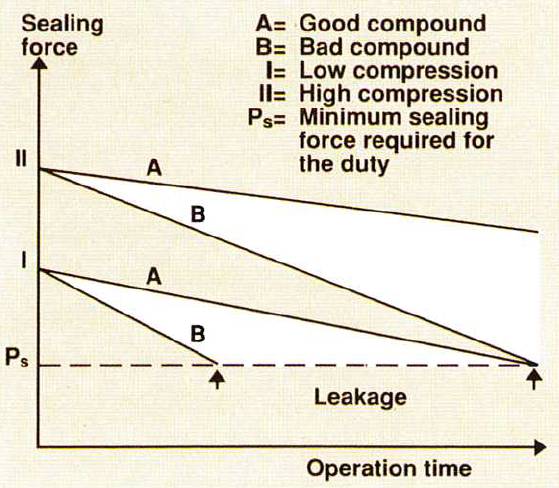

The chemical composition of a gasket will determine its lifespan and ability to handle various media; low quality gaskets (or those that are not proofed for the work) may not be able to withstand the operating conditions of the heat exchanger unit.

For example, EPDM (a synthetic polymer), is known for its resistance of corrosive media and its ability to withstand higher temperatures. However, EPDM swells in reaction to oils, contributing to premature degradation of the gaskets within a unit. In such a case where oil comes in contact with the gaskets, NBR (nitrile rubber) would be a more suitable choice; understanding the strengths and weaknesses of various materials allows you to choose gaskets that last longer, prevent unforeseen accidents and downtime of your process, and reduce the need for servicing over the lifespan of your plate heat exchanger unit.

Structure & Composition

The gaskets used in plate heat exchangers are complex organic systems, and are the result of extensive performance testing and industrial research. Their compositions are designed and engineering on a molecular level to achieve the ideal elasticity and attain properties that are suitable for dealing with certain process media.

Vulcanizing chemicals (such as sulfur) allow substances to bind, creating cross-linked polymeric substances. This allows the native polymer to be combined with components that possess the necessary properties of a heat exchanger gasket.

Fillers contribute to the volume and rigidity of the rubber, while providing resistance to tension. Carbon black, a commonly-used industrial filler, gives gaskets their distinct colouration.

Anti-degradants prevent the natural aging of the rubber by compounds and atmospheric elements during operating processes.

Research

Valutech works with industry leaders, such as Alfa Laval, who work year-round in an effort to research and test potentially beneficial gasket components. The following is Alfa Laval’s thorough six-step process to determine whether a new material is ideal for use in their gaskets:

- Study previous experiments.

- Subject approximately 10 promising rubbers to a variety of physical and chemical tests for up to 5 months.

- Use the best of these rubbers in heat exchangers for up to a year.

- Assess feasibility of industrial-scale production.

- Further practical testing of the best materials for up to a year; this stage includes response to media flow, as well as cleaning and servicing.

- Approve suitable materials for mass production and finalize the recipe, ensuring consistent manufacturing according to said recipe.

Not the service that you’re looking for?

Click here to see the other services we offer.