Alfa Laval LKH Prime Pumps

Self-Priming Pumps For CIP and Product Transfer Duties

The Alfa Laval LKH Prime line of pumps is based on the market-leading LKH line, and is designed for quiet and efficient operation under the strictest hygienic conditions in the food and beverage, dairy, personal care, and pharmaceutical industries.

The flexibility of these self-priming pumps allows for the handling of process fluids, as well as tank-emptying and entrained air CIP duties. The LKH Prime line of pumps is the ideal replacement for the now-obsolete MR Liquid Ring line of pumps, offering higher efficiency and lower noise levels for CIP return applications. This leads to simplifications in piping and control system design, minimizing costs and contamination risk.

Features and Model Comparisons

|

The following models are available in the LKH Prime line: |

||||

|---|---|---|---|---|

| LKH Prime Model | LKH Prime 10 | LKH Prime 20 | LKH Prime 40 | |

| Connection Size (Inlet) in inches | 2 | 2.5 | 3 | |

| Connection Size (Outlet) in inches | 2 | 2 | 2.5 | |

| Approx. Max Flow Rate at 3000 RPM in US Gal/m |

150 | 310 | 440 | |

| Max Differential Pressure in psi | 47 | 57 | 109 | |

| Power in horsepower | 3-60 | |||

LKH Prime Line Features:

- The LKH Prime line supports flow rates of up to 440 US Gal/min, and differential pressures of up to 109 psi.

- Shares common parts with the LKH line of pumps, reducing maintenance costs.

- LKH Prime pumps are equipped with a single mechanical shaft seal as standard; a double mechanical seal is available optionally.

- Front-loading shaft seal with spring and washers mounted on atmospheric side, making replacement of the shaft seal take only minutes.

- Supplied with 4 adjustable stainless-steel legs.

- Impeller can be trimmed for any application.

- Available with UltraPure finish and Alfa Laval Q-doc, a comprehensive documentation package meeting the standards required for the pharmaceutical industry.

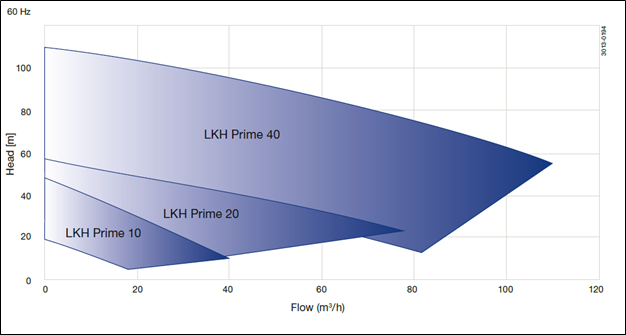

The LKH Prime line adheres to the following curves:

Alfa Laval’s LKH Prime line of pumps is available in an UltraPure finish to cover the needs of virtually every application in the pharmaceutical, biopharma, and personal care industries while adhering to the strictest hygienic regulations.

All UltraPure models feature the following:

- A greater level of attention to hygienic design and repeatability to reduce the risk of contamination.

- Robust designs that are time-tested and proven in the pharmaceutical industry.

- Full documentation of the production chain, from raw materials to delivered equipment, ensuring repeatability and batch quality.

- Alfa Laval’s online Q-doc documentation system; it is based on GDP (Good Documentation Practice), providing full product details and assisting in processes qualification and validation.

For more information on the Twin Screw please click here; additional dimensional data available upon

request.

Not the pump you’re looking for?

Browse our full selection of sanitary pumps.