I. INTRODUCTION

The Brazed Plate Heat Exchanger (BHE)

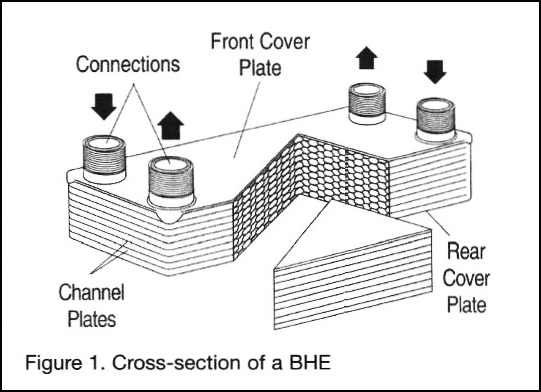

Alfa Laval is credited with inventing the original brazed plate heat exchanger. The brazed heat exchanger is a compact variation of the traditional plate heat exchanger. But, unlike the traditional plate heat exchanger, the BHE does not have a carbon steel frame, gaskets, tightening bolts or carrying bar. It consists simply of AISI 316 stainless steel corrugated channel plates, a pressure plate and a frame plate with connections that are brazed together in a vacuum furnace.

How It Works

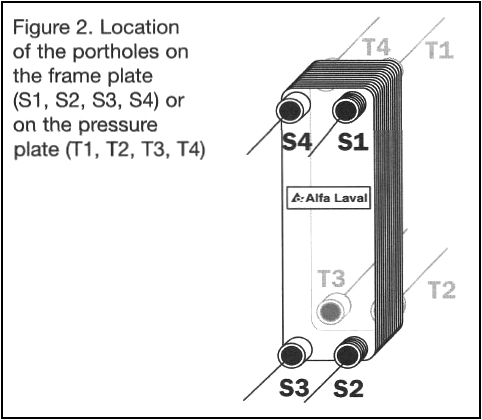

When the plate pack is compressed, it creates a continuous series of channels with portholes in each of the four corners. The media enters the inlet connections and is distributed into the narrow channels between the plates. The passages between the plates and comer portholes are arranged so that the two heat transfer media can travel in alternate channels.

A brazed seal around the outer edge of the plates retains the media within the channels. As the warmer medium passes through the unit, it releases heat energy to the thin plate wall, which instantly transfers it to the colder medium on the other side.

The thin plates have a uniquely designed herringbone geometry that creates high turbulence and low pressure loss. This optimal plate pattern gives the BHE an extremely high overall heat transfer coefficient. This pattern has been developed through theoretical consideration, checked by laboratory tests and proven itself in the field.

II. THE ALFA LAVAL BRAZED HEAT EXCHANGER SERIES

The Copper-Brazed Heat Exchanger Line

Alfa Laval has developed a standard line of BHEs to encompass different applications and heat loads. These heat exchangers, are brazed with 99.9% pure copper.

Brazed Heat Exchangers are suitable for liquid/liquid, steam/liquid, and gas/liquid applications.

Standard BHEs

Since there are a great number of possible BHE design combinations, Alfa Laval offers standard and custom-designed BHEs. The standard BHEs have a preset number of plates and connections. These units are available off-the-shelf and can be delivered within a few days. The standard line is ideal for the customer who requires only a small number of units. The custom designed BHE is designed exactly according to the customer’s specifications. The delivery time is therefore initially longer than a standard BHE to allow time for production.

Custom-designed BHEs

Custom-designed BHEs can be equipped with:

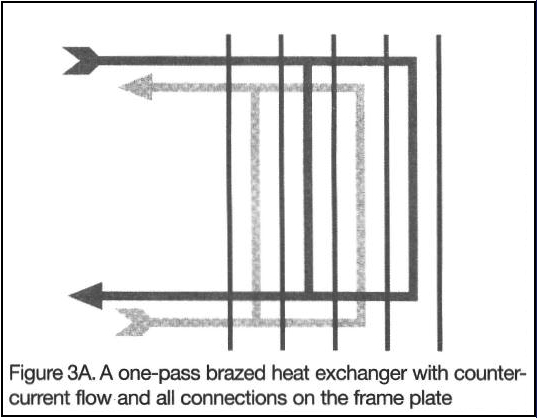

- multiple passes

- different connection positions

- non-standard connections

- three-media configurations

Multi-pass BHEs

Multi-pass units are used to increase the thermal length of the heat exchanger. With this design, more heat is transferred from the hot medium to the cold medium, at the expense of a higher pressure drop. Figures 3 illustrate the difference between a one and two pass design.

III. BRAZED HEAT EXCHANGER SPECIFICATIONS

Fluid quality

To minimize risk of corrosion, the media pH values should be neutral. The media must not contain chemicals corrosive to stainless steel (AISI 316) or the brazing material (copper or nickel). Stainless steel is especially sensitive to localized spot and crevice corrosion due to chloride, sulfite and sulfate ions. Above a critical ion concentration the passivity of the steel breaks down and local spot corrosion occurs.

Materials

- Plates and connections AISI 316 Brazing material

- CB units Copper 99.9%

Approval

- Sweden: Statens Anlaggningsprovning (SA)

- Germany: Technische Uberwachungsverein

- USA: Underwriters Laboratories (UL)

- American Society of Mechanical Engineers (ASME) – upon request for some models

- Canada: Canadian Standards Association (CSA)