Alfa Laval AlfaCond Condensers

Efficient Plate Condensers Designed for Use in a Vacuum

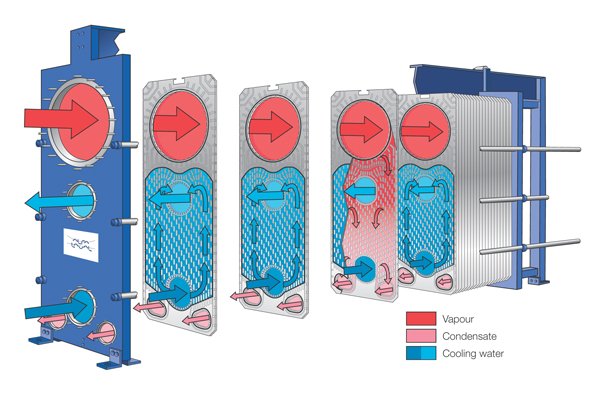

AlfaCond is the world’s first plate condenser specifically designed for condensing under vacuum.Their compact design means they are a space-saving, efficient alternative to shell-and-tube condensers; they are also used in place of direct condensers when recovery of the condensate is a key factor. AlfaCond heat exchangers have a flexible configuration, with sub-cooling of the condensate as an option. They are ideal for use in the bioethanol and sugar industries as ethanol, and pan-vapour condensers, respectively.

AlfaCond units feature pressure plate rollers and a 5–point alignment system with reinforced hangers for quick opening and closing of the exchanger without heavy tools, all while minimizing damage to the unit. They can be cleaned mechanically or by using CIP (Cleaning–in–Place), and are also available with glued gaskets.

Product Specifications

See model comparisons, product benefits, and how it works below:

|

Please refer to the following comparison to choose the right model for your application: |

|||

|---|---|---|---|

| AlfaCond Model | 400 | 600 | 800 |

| Max Design Temp. in °F (°C) | 320 (160) | ||

| Max Design Pressure in psig (barg) | 90 (6.2) | ||

| Height in inches | 87.3″ | 112.6″ | 125.6″ |

| Width in inches | 24.3″ | 35″ | 44.6″ |

| Inlet Port Diameter in inches | 16″ | 24″ | 30″ |

| Free Channel (average plate gap) in inches |

0.43″ / 0.12″ | ||

AlfaCond offers the following

benefits over equivalent shell-and-tube

and non-configurable plate condensers:

- Optional sub-cooling of the condensate and non-condensable gasses

- Easy installation, high serviceability, and simple maintenance

- Flexible Configuration

How it Works

AlfaCond units have a unique inlet port configuration designed specifically for

low-pressure and vacuum condensation duties.

The sealing between plates on AlfaCond units alternates between laser welds and gaskets; vapour condenses in the welded channels while cooling utilities pass through the gasketed channels.