Chemicals, Steel, and Heavy Manufacturing

Valutech provides heat transfer and industrial valve products for organic and inorganic chemical manufacturing applications such as polymer and acid production, as well as steel industry applications including furnace water and off-gas cooling, while also being active in other heavy manufacturing industries. For more information on each industry and the solutions and services that Valutech provides to support them, please select the relevant industry from the boxes to the right.

Chemical Production

Process Equipment Solutions and Expertise for Core Chemical-Producing Industries

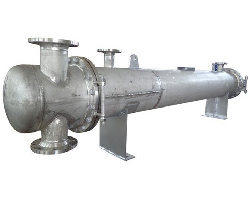

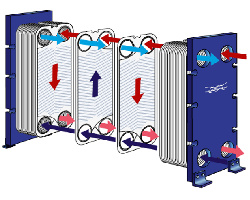

The chemical manufacturing industry is comprised of critical sectors that act as the backbone to a wide array downstream industries that use their chemical product outputs as raw inputs in their processes. The pharmaceutical, automotive, consumer goods, agriculture, and other industries depend on tens of thousands of manufactured chemical products from basic acids and solvents to plastics and advanced materials in order to keep their business operating and growing. Chemical plants and refineries have a wide range of heat transfer and fluid handling needs that heat exchangers accommodate — this includes but is not limited to: heating, cooling, condensing, evaporating, reboiling, and desuperheating. Plate-and-frame and shell-and-tube heat exchangers are commonly used as condensers and reboilers for distillation and stripping columns, as well as heaters and coolers for steam, water, acids, and solvents. More demanding applications can demand specialized units such as fully-welded and semi-welded plate-and-frame or spiral heat exchangers. In addition to selecting a suitable style of heat exchanger, it is imperative to size and configure the unit to the demands of the process while accounting for long-term usage effects and eventual process modifications. Valutech supplies Alfa Laval plate-and-frame and spiral heat exchangers, as well as Doyle & Roth and Enerquip shell-and-tube heat exchangers with high heat transfer efficiency and options for corrosion resistance, low footprint variants, and other size and material configurations to suit all chemical processing needs. Please click below to find the heat exchanger suitable for your process:

Versatile, maintenance-free plate heat exchangers for extreme operating conditions.

Ideal for fluids containing up to 8% w/v solids or fibres up to 12mm in diameter.

The chemical manufacturing industry can be broadly divided into organic and inorganic chemical production. The former refers to the manufacturing of chemicals derived from carbon-containing compounds such as petrochemicals, plastics, polymers, and alcohols, while the latter includes production of hydrochloric acid, hydrogen peroxide, soda ash, fertilizers, and sulphuric acid, among others. The inorganic chloralkali process produce chlorine, sodium hydroxide, and hydrogen as commodity chemicals for a wide variety of industries; applications for heat exchangers include brine pre-treatment, wet chlorine gas  cooling, hydrogen gas cooling and electrolyte heating and cooling. Products dependent on the petrochemical sector include packaging materials, automobiles, plastic bags, and household appliances. Preheating of crude oil before distillation, overhead vapour condensation, process stream heating and cooling in catalytic cracking and waste stream heat recovery in steam reforming are just some examples of the many possible uses of heat exchangers in this sector. The fine and specialty chemicals sector involves production of vitamins, pesticides, water treatment chemicals, surfactants, adhesives, resins, and other substances that require specialty heat exchanger solutions. Heat exchangers are even used in growing ‘bio-chemical’ sectors, where plants such as crops, trees, and algae, as well as bacteria and biological waste are used to produce bio-based chemicals, fuels, and product intermediates; for example, plate heat exchangers are used as evaporators to concentrate sugar and lignin in cellulose-based sugar and ethanol production processes.

cooling, hydrogen gas cooling and electrolyte heating and cooling. Products dependent on the petrochemical sector include packaging materials, automobiles, plastic bags, and household appliances. Preheating of crude oil before distillation, overhead vapour condensation, process stream heating and cooling in catalytic cracking and waste stream heat recovery in steam reforming are just some examples of the many possible uses of heat exchangers in this sector. The fine and specialty chemicals sector involves production of vitamins, pesticides, water treatment chemicals, surfactants, adhesives, resins, and other substances that require specialty heat exchanger solutions. Heat exchangers are even used in growing ‘bio-chemical’ sectors, where plants such as crops, trees, and algae, as well as bacteria and biological waste are used to produce bio-based chemicals, fuels, and product intermediates; for example, plate heat exchangers are used as evaporators to concentrate sugar and lignin in cellulose-based sugar and ethanol production processes.

Regardless of the sector, heat exchangers play a pivotal role in temperature management of reactors, distillation columns, and fluid streams with many applications containing viscous or fibrous liquids, slurries, air-to-gas heat transfer, corrosive fluids, and high pressures and temperatures. Valutech supplies solutions to accommodate all of the above process conditions and the expertise to recommend the optimal solution, as well as offering spare parts and servicing for plate heat exchangers, making Valutech the one stop shop for long-term, sustainable heat transfer solutions for virtually all chemical production processes.

Steel Manufacturing Processes

How Plate Heat Exchangers Improve Plant Efficiency and Production Sustainability

The steel manufacturing industry is a cornerstone of global construction and manufacturing economies, with production involving some of the most energy-intensive processes seen in any heavy manufacturing sector. The industry as a whole is trending towards high efficiency in excess heat dissipation solutions and improvements in process efficiencies to minimize emissions. Traditional production is performed in a process known as integrated steel production, where coal is converted to coke and subsequently heated in the presence of iron ore and limestone in a blast furnace to produce molten (pig) iron. This iron is then exposed to oxygen in a basic oxygen furnace to produce steel, which is then cast to obtain semi-finished products like bars and slabs. The diagram below illustrates the integrated steel production process by which steel products have traditionally been made using basic oxygen furnaces:

In addition to integrated steel production, there are processes such as secondary processing of scrap steel and direct resolution of iron ore pellets that use electric arc furnaces to produce steel products — see the diagram below for an overview of the process:

As evidenced in the diagrams, heat-producing furnaces are central to the production process. Heat exchangers are used to manage and maintain optimal furnace temperatures via water loops regardless of the furnace style — this makes the efficiency of process heat exchangers crucial to ensure sustainable long-term operation without sacrificing excessive floor space with massive units. In this respect, plate heat exchangers are a very suitable option due to their low floor space requirements for the high heat transfer efficiency they offer. The diagrams above illustrate the steel manufacturing process for the various production methods; in addition to furnace temperature regulation, heat exchangers can be used for the following applications within steel manufacturing processes:

- Cooling of sinter gas (carbon monoxide, carbon dioxide, and nitrogen oxides) before treatment and release or reuse within the process;

- Cooling of reducing gas (hydrogen and carbon monoxide) from direct reduction processes before treatment and release or reuse within the process;

- Cooling of off gas from furnaces prior to release or recycling.

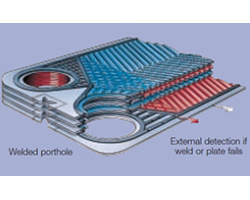

In all of the above cases, the heat recovered can be transferred to water for the production of steam to be used in plant operations. The versatility and configurability of plate heat exchangers makes them an optimal solution for virtually all heat transfer requirements in steel plants and rolling mills that produce steel slabs, billets, plates, sheets and beams in complex and energy-intensive processes involving vast amounts of heat. Plate heat exchangers offer additional advantages over shell and tube heat exchangers in applications such as cooling of lubricating oils (e.g. MORGOIL®) for gears and bearings and other oils used in transformers: the guarantee of contamination-free operation. The use of double-walled plate heat exchangers eliminates the risk of cross contamination of lubricating fluids and cooling media and the costly cleanup, plant downtime, and environmental contamination associated with a leak, all while maintaining a compact footprint and efficient heat transfer.

Steel manufacturing plant design is trending towards the use of closed-loop cooling systems that create two independent cooling water circuits: high-quality water as the primary cooling system within the process itself, and a secondary loop of water from a nearby water source to cool the primary loop. Plate heat exchangers facilitate the cooling of the primary loop using water sourced from a cooling tower or nearby body of freshwater or saltwater; this reduces maintenance requirements since the high-quality primary loop is isolated from the secondary loop which will inevitably contain particulates and contaminants. This also lowers pumping costs since the pumps used only need to overcome the pressure losses of the process equipment rather than the full cooling tower. Since plate heat exchangers are significantly simpler to maintain and service than furnace water loops and other process equipment, closed-loop systems will greatly extend the lifetime and reduce maintenance needs of the rest of the process. The use of double-walled designs in this application adds further protection to both sides of the loop: the primary loop is further protected from particulates introduced from the secondary loop, while the secondary loop is isolated from oils and other process fluids that can enter the primary cooling loop. Thus, proper use of plate heat exchangers offers the benefit of preventing unintentional environmental discharge within in an increasingly strict regulatory landscape, in addition to benefits expressed in lower operating costs.

In addition to plate heat exchangers, Valutech offers disk stack and decanter style centrifuges for oil separation, as well as spiral heat exchangers, coolers, and filters for various applications within steel production processes.

Heavy Manufacturing Industries

Heat Exchangers and Process Equipment for Large-Scale Material and Machinery Production

Heavy manufacturing industries refer to the on the production of large-scale goods such as machinery, vehicles, industrial equipment, and infrastructure components. This sector supports other industries by supplying essential raw materials such as steel and machinery like drilling equipment and furnaces. Subsets

of the heavy manufacturing industry include steel production, shipbuilding, aerospace, and heavy machinery production, among others. These sectors often involve complex and energy-intensive processes, meaning equipment has to be rated to support high temperatures, pressures, and large material volumes. Valutech supplies the heat exchangers listed above, as well as steam traps, control valves, and check valves to meet the heat transfer and fluid handling needs of virtually every heavy manufacturing process of any scale. Valutech also supplies the following:

- The complete product line of Check-All industrial check valves, which can be used in virtually every industrial application to prevent backflow and are used in flow-control applications such as priming pumps, maintaining head pressure, line isolation, vacuum breaker, media injection, and many others.

- Gestra steam traps for use in industrial condensate removal applications including pipe and boiler drainage, frost protection, condensation management in heat exchangers and distillation columns, and many others.