Sanitary Heat Exchangers

Efficient Heat Transfer for all Fluids in Your Hygienic Process

Valutech carries a complete range of sanitary heat exchangers that are designed for use within the food & beverage, dairy, pharmaceutical, bio-pharma, cannabis, and personal care industries. We offer solutions for systems with fluids of all viscosities, with or without suspended solids, pulps, and/or fibers, all while handling shear-sensitive and heat-sensitive media with the highest efficiency. We also offer plate-and-frame and shell & tube units specifically designed for CIP applications.

A summary of the sanitary heat exchangers Valutech carries is listed below, along with the available models in each category; for more information on the full selection of units within a specific category of heat exchangers, please click on the respective image.

Sanitary Heat Exchangers

Find the line and model that is right for your hygienic process below:

Alfa Laval is globally affiliated with major pasteurizer system manufacturers; their sanitary plate-and-frame heat exchangers are designed for gentle treatment of fluid media within the food & beverage, pharmaceutical, personal care, cannabis, dairy, and bio-pharma industries, and they are available with a wide variety of plate materials and patterns.

Available Models: HygienicLine, FrontLine, FrontLine Automatic, BaseLine

Designed for use high temperature/pressure processes within the food, beverage, personal care, pharmaceutical, cannabis, electronics, and dairy industries, Enerquip shell and tube heat exchangers are 3-A and FDA compliant, with numerous alloys, connection types, options, and finishes.

Enerquip units are available in U-tube, straight tube, and coil varieties, and are particularly suited to pharma-grade applications with double sheet tubes as an option.

Specifically designed for CIP duties in processes with high hygienic standards, these low-footprint models provide simple, in-line cleaning of process equipment without dismantling of said equipment.

All models are highly effective at heating CIP fluid in order to remove scale, product deposits, and bio-fouling.

Available Models: TS6-M, Sanitary Shell and Tube, AlfaNova, CB Brazed Plate Heat Exchangers

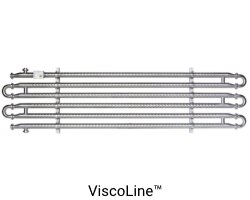

Alfa Laval’s ViscoLine™ units feature modular design as well as corrugated profiles, and are intended for gentle heating and cooling applications of sensitive, low to medium viscosity liquids containing suspended particles. Alfa Laval’s Pharma-line Point of Use unit is a plug-and-play module for the cooling of pharmaceutical water systems, meeting the most stringent hygienic industrial standards, even when on standby.

Available Models: ViscoLine™, Pharma-line Point of Use

Alfa Laval Contherm® units are designed to handle medium to high viscosity fluids that are prone to fouling heat exchangers in continuous and semi-continuous hygienic applications. They are suitable for viscous, particle-containing, and phase-changing media.

The Contherm® Core is a more economic option for the handling of lower viscosity fluids.

Available Models: Contherm®, Contherm® Core