Stainless-Steel Fusion Bonded Plate Heat Exchangers

Unique Complete Stainless-Steel Construction for Industrial, Hydronic, and Hygienic Applications

Fusion bonded plate heat exchangers feature the conventional advantages of a brazed plate heat exchanger, while also providing high levels of corrosion resistance and usability within the strictest sanitary applications, such as clean water refrigeration chillers and tap water heating systems. They are commonly used within a wide array of industrial heating and cooling, comfort heating, process industry, air conditioning, and refrigeration applications, among others. Their corrosion resistance allows for use of refrigerants such as ammonia, or in district heating installations with corrosive water.

Valutech carries the complete line of Alfa Laval Stainless Steel Fusion Bonded Plate Heat Exchangers.

Find and compare the AN Series models suitable for your application below:

| AN Model | AN27 | AN52 | AN76 |

|---|---|---|---|

| Connection Size (NPT) in inches | 1″ | 2″ | |

| Max Number of Plates | 100 | 150 | |

| Standard Temp. Rating in °F | 300 | ||

| Standard Pressure Rating in psi | 400 (Weld connections available for high pressure units) | ||

Fusion bonded plate heat exchangers are formed using a 100% stainless steel construction, fused with Alfa Laval’s patented AlfaFusion technology. The units consist of a pack of corrugated plates portholes for input/output of the media. Their construction allows for operation under extreme pressures and temperatures (550 °C/1200 °F) relative to standard brazed plate units.

The construction of these units does not include gaskets, making them ideal for applications where aggressive process media or other conditions could damage the gaskets that would be used traditionally in gasketed-plate heat exchangers. Internal, shock-proof contact points hold together the plate pack, without the need for external frame plates for design pressures up to 70 bar (1015 psi). The edge of the plates and the plate-plate contact surfaces are also fusion-bonded, reinforcing against internal media pressure.

AlfaNova units are subjective to exhaustive pressure, thermal and corrosion resistance tests, ensuring maximum safety, reliability, durability. The construction of these models allows for optimal heat recovery due to attaining close (2°F) temperature approaches.

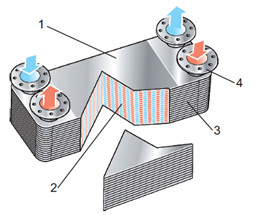

1: Cover Plate

3: Seal

2: Corrugated Plates

4: Ports

1: Cover Plate

2: Corrugated Plates

3: Seal

4: Ports

Other applications of AlfaNova units include:

- Ammonia Compressor Oil Cooling

- Ammonia Economizer

- Ammonia Evaporator (DX or Thermo-siphon)

- Ammonia Condenser

- Ammonia De-superheater and Heat Recovery

- Absorption Chillers – can be used with corrosive liquids (e.g. lithium bromide solutions), used as the high temperature regenerator.

- Clean Water Chiller

- Industrial/Hydraulic Oil Cooling

- Ammonia Compressor Oil Cooling

- Ammonia Economizer

- Ammonia Evaporator (DX or Thermo-siphon)

- Ammonia Condenser

- Ammonia De-superheater and Heat Recovery

- Absorption Chillers – can be used with corrosive liquids (e.g. lithium bromide solutions), used as the high temperature regenerator.

- Clean Water Chiller

- Industrial/Hydraulic Oil Cooling