Immersion Plate Coil

Clamp On Plate Coil

What is a Temp-Plate® Plate Coil Heat Exchanger?

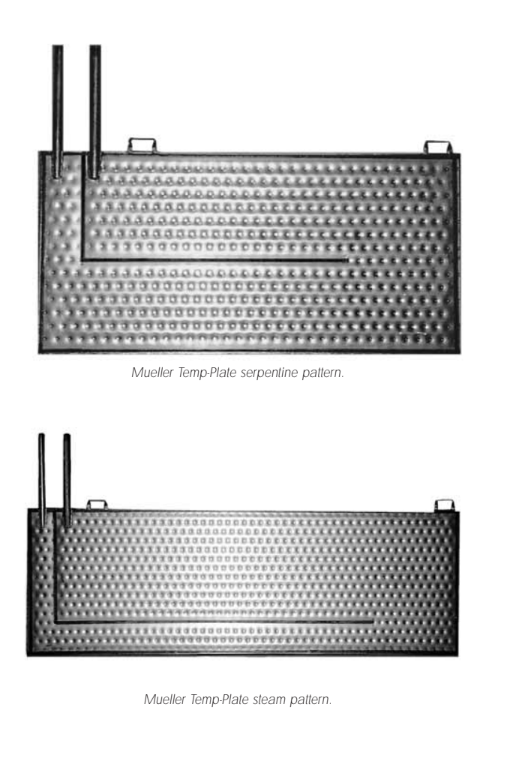

Constructed of two sheets of stainless steel, titanium Grade-1, or high alloy metals that are spot welded and seamed around the edges to create a single panel. After the panel is welded, it creates space for the flow of a heating or cooling medium that keeps a constant and turbulent flow between the welded panels.

A plate coil heat exchanger can be welded, formed or designed to meet your exact needs with irregular shapes, high pressures, or corrosive environments. Designed to meet nearly any application, Temp-Plate Coils can be used as an immersion, clamp-on, or integral heat transfer surfaces.

Valutech can work with you to find the best application for your heat transfer equipment needs in a wide variety of industries. Whether it be in chemical processing, metal finishing, automotive, energy recovery, etc. – Applications for Plate Coils go as far as the imagination will take you.

Immersion Plate Coils for Tank Heating or Cooling:

Mueller Plate Coils are cost-effective replacements for pipe coils in immersion heating and cooling applications. They offer amplified turbulent flow on both the service and process sides; making them more efficient than pipe coil type heat exchangers.

Our Plate Coils are custom manufactured to your needs and can be banked together for applications requiring large heat transfer surfaces.

Clamp-on Plate Coils for external Tank heating or Cooling:

Our double embossed Temp-Plate® Clamp-On Assemblies will allow your process to be more efficient. Through testing and research, our engineers have proven that the thermal efficieny, also known as the U value, is better with double embossed clamp on assemblies over single embossed designs.

Our clamp-on heat transfer equipment can be crafted, welded, and applied to your system with minimal to no equipment downtime depending on your application. Paul Mueller Company provides high-grade materials, impeccable design, and experienced craftsmanship to create highly versatile heat transfer that will integrate into your system and boost the success of your business.

Product Applications

Temp-Plate heat transfer surface has multiple applications in industries. Paul Mueller Company manufactures Temp-Plate in a great variety of styles, sizes, and materials for a multitude of purposes. For example:

- Banks of Temp-Plate for: cooling coffee extract, cooling quench oil, cooling waste water while heating make-up water, cooling water for fish hatcheries, heating a city’s water supply with boiler condenser water, heating lard, separating moisture from crude oil.

- Circular flat sections for inside bottoms of processing tanks

- Clamp-on sections for shells, cones, and heads.

- Cooling shell sections for field-erected brewery fermenting tanks.

- Cryogenic shrouds for mirror fusion energy

- Drying shelves for textiles and pharmaceuticals

- Evaporator pans for paper producers

- Fluidized bed dryers

- Freeze-drying shelves

- Ice-making plates

- Immersion sections for: brine chilling, chilling wine, cooling, anodizing solutions, drying powdered mill

- phosphate tanks, heating or cooling metal cleaning and plating

- tanks, heating wire drawing solutions

- Internal baffles for tanks with agitators

- Interior cooling sections for yeast propagators

- Jacketed troughs

- Large internal baffle assemblies for cooling vegetable oil

- Vacuum drums